14

CLEANING AND MAINTENANCE

CLEANING

Please follow the maintenance and cleaning guidelines below to keep your cooktop in good working

order.

The cooktop should be cleaned regularly with all stains and boil overs being cleaned up. Do not allow

stains and boil overs to become burnt onto the appliance. Avoid using chlorine based cleaners (like

bleach). Do not use steam or high pressure cleaners on the appliance.

Avoid leaving acidic or alkaline substances on the cooktop.

Please ensure the cooktop is cold when cleaning, to avoid burns from hot components.

Try to minimise the use of specialized cleaning products. Attempt to clean with soapy water and a

sponge. If this is not successful, a mild cleaner can be used.

Do not use abrasive cleaners or scourer type pads to clean the appliance. These can damage the

tempered glass.

Burners and enamelled components are only to be washed with soapy water and sponges. Do not use

abrasive cleaners on these components.

When cleaning the burner components, please ensure that they are fully dry before replacing them on

the cooktop and before use.

Ensure that all components are placed back onto the cooktop correctly. Failure to do so can cause

problems with the burners igniting and functioning correctly.

For semi-rapid and rapid burners, first place the brass burner skirt over the burner body, so that the

extruded section at the base is sitting over the injector. Rotate the brass burner skirt until the slots

match up with the ignitor and sensor pins. Place the brass burner skirt into the burner body so that it

fits snuggly and level. The brass burner skirt should lock into position so it cannot be rotated. Secondly

place the steel burner cover evenly on the four extrusions at the top of the brass burner skirt.

For wok burners, the first operation is similar to that for semi-rapid and rapid burners. Once positioned,

there are two steel burner covers to be placed on top of the brass burner skirt. The outer burner cover

sits evenly over the outer chamber of the brass burner skirt, and the inner burner cover sits evenly on

the three extrusions at the centre of the brass burner cover.

MAINTENANCE

Clean the tempered glass cooktop as above after every use.

Clean brass burner top and trivet at least once a week, or after any spillage.

Gas inlet pipes should be checked periodically for leakages (see section on leak testing) a minimum of

every 12 months.

Lubrication of gas valves - this can only be performed by an authorised person. It may be required if the

gas tap become stiff and difficult to turn.

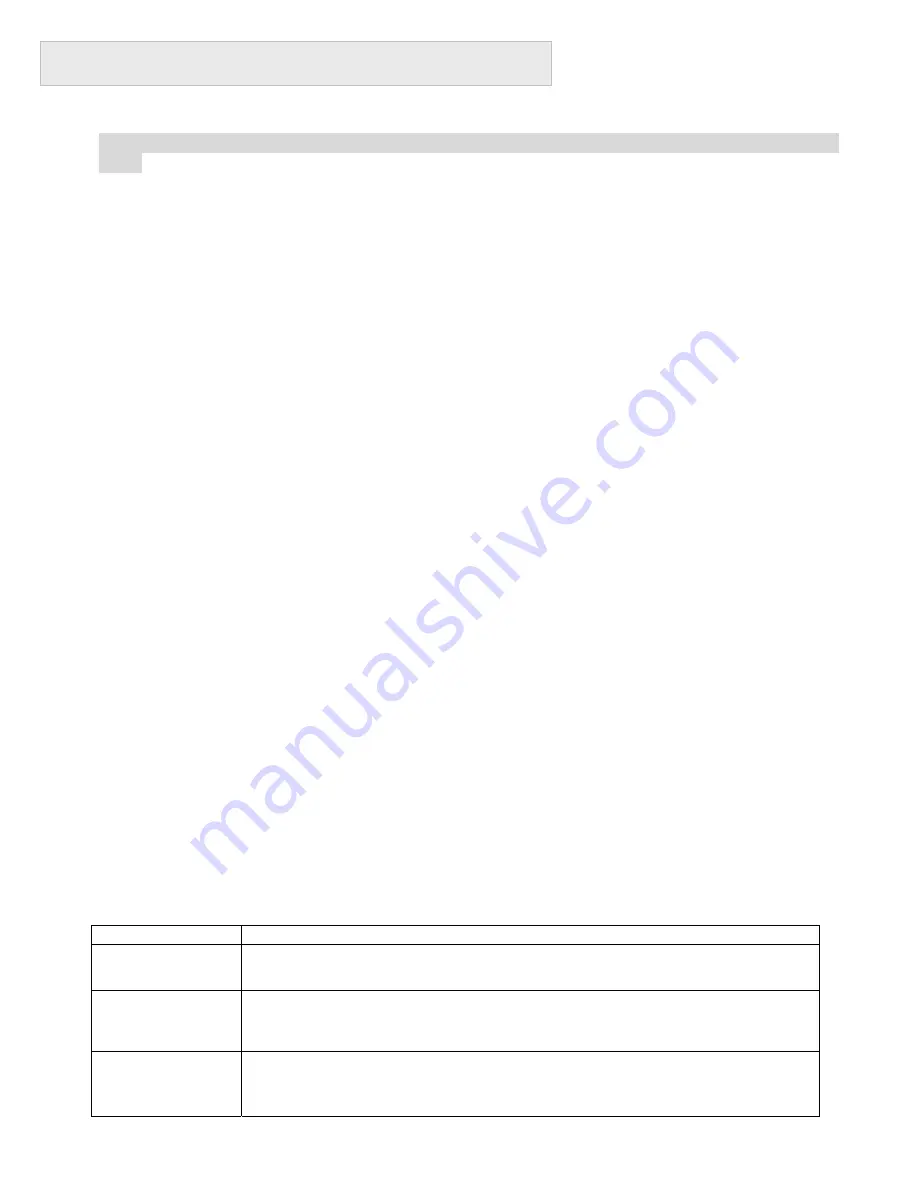

FAULT FINDING CHART

Fault

Possible cause (corrective action)

No spark / No ignition of

gas.

Power outage, appliance power turned off at isolation switch, fuse blown / tripped, no gas to the

appliance (check supplies). Spillage of liquid over burner (clean up spillage on burner components).

Burner not assembled correctly (Refer to assembly instruction manual).

Burner ignites but flame

goes out when control

knobs released.

Control knob not depressed down enough when igniting burner, control knob being released from the

ignition mode too early (try ignition again). Spillage of liquid over burner (clean up spillage on burner

components). Burner not assembled correctly (Refer to assembly instruction manual). Faulty

thermocouple (technician call out required call Omega service centre).

Erratic / Abnormal

flames or noise when

operating the appliance.

Burner not assembled correctly (Refer to assembly instructions). Spillage of liquid over burner (Clean up

spillage on burner components). Oversize cooking vessel being used on the appliance (use smaller

cooking vessels). Internal ignition of burner (Turn off gas and reignite burner). Wrong gas type being

used (check supply and data labels).