8

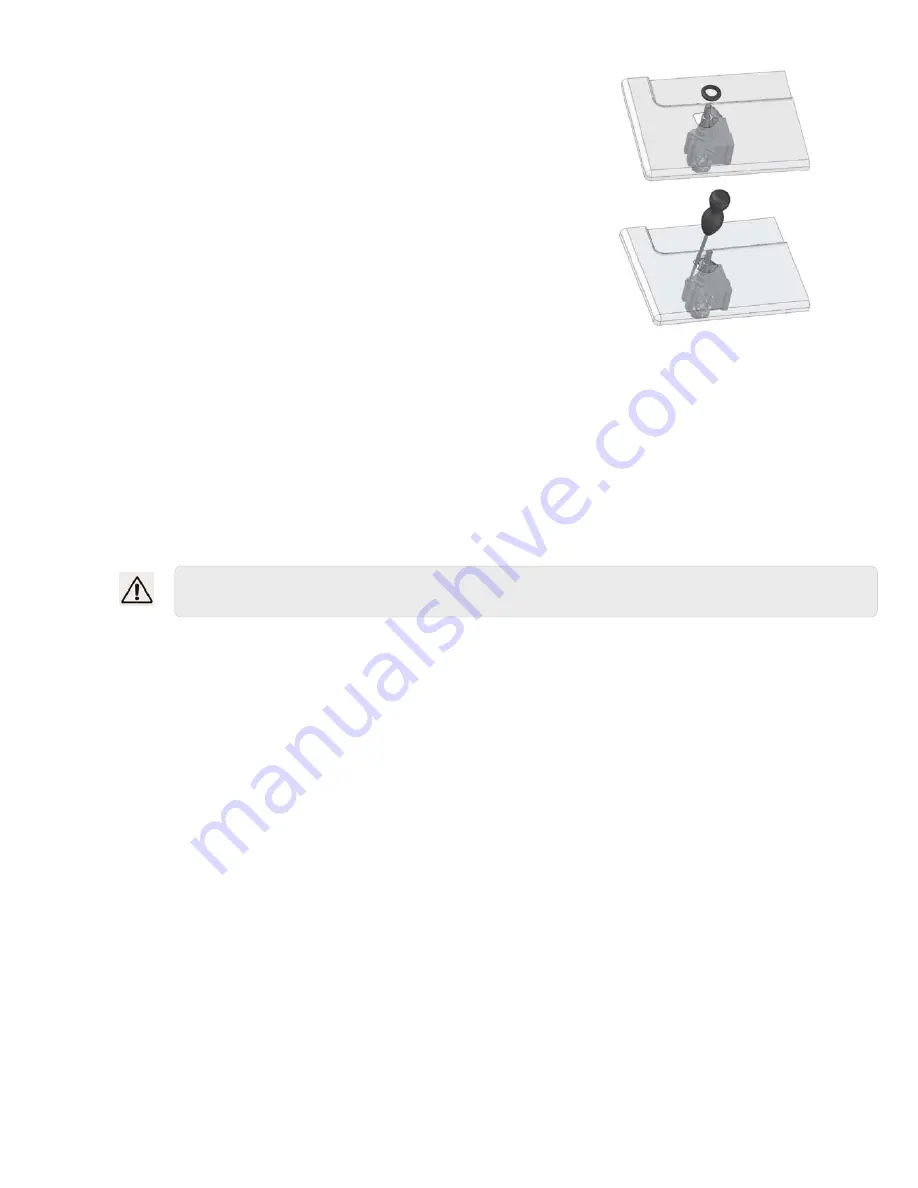

ADJUSTING THE MINIMUM SETTING ON THE VALVE

When switching from one type of gas to another, the minimum flow rate

must be adjusted at the valve. The flame should not go out even when

passing suddenly from maximum to minimum flame.

The gas valves are supplied with an adjustment screw on the valve body

side.

Using a screwdriver with Ø3mm max, turn the screw on the valve body

side until the correct setting is obtained. For ULPG, turn the screw fully

clockwise (closed). For NG, first turn the screw fully clockwise. Carefully

turn the screw anti-clockwise by the following amount:

Semi-rapid burner: 3/8ths of a turn.

Rapid burner: Slightly less than 5/8ths of a turn.

Wok burner: ½ a turn.

This will allow more gas to flow through the valve at the minimum control

knob setting.

This can be checked after the gas has been connected by running the cooktop for a 10 seconds MAX and then

quickly turning down to MIN. If the flame stays lit, the minimum setting on the valve is correct.

LEAK TESTING

1.

Make sure gas control knobs are Off and turn the cylinder valve On.

2.

Check for leaking joints by brushing with solution of half-liquid detergent and half water. If a leak is present,

bubbles will appear (or you may hear a hissing sound). Retightening connections can generally repair a

leaking joint. You must also check the gas hose and connection at the gas cylinder. If a leak cannot be

resolved, do not proceed.

DO NOT USE NAKED FLAME FOR LOCATING GAS LEAKS.

IF A LEAK PERSISTS CALL AN AUTHORISED GAS FITTER.

NOTE: If an appliance cannot be adjusted to perform correctly, contact the Omega service department on 131

NPK.