3

1. SAFETY WARNINGS

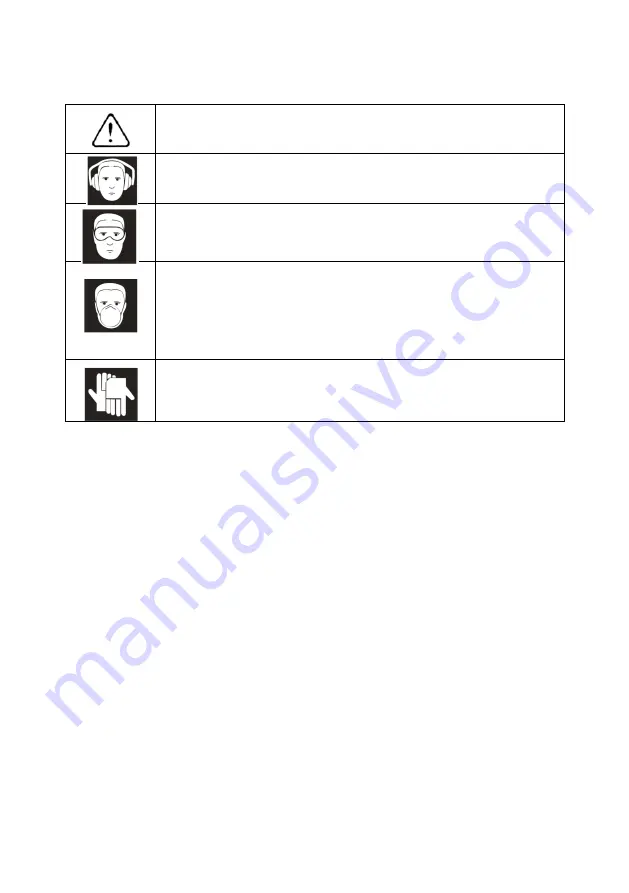

SYMBOLS

In this manual and/or on the machine the following symbols are used:

Locate the spray gun in a suitable work area. Keep this area clean and tidy and free from

unrelated materials. Ensure that there is adequate ventilation and lighting.

Familiarise yourself with the application, limitations and potential hazards peculiar to the

spray gun.

WARNING!

Disconnect the spray gun from the air supply before changing accessories,

servicing or performing any maintenance.

Maintain the spray gun in good condition (use an authorised service agent).

Replace or repair damaged parts. Use authorised parts only. Unauthorised parts may be

dangerous and will invalidate the warranty.

Keep the spray gun clean for best and safest performance.

Ensure that the compressed air system can supply the spray gun air consumption for the

model to be used.

Wear approved safety respiratory protection and safety eye goggles.

If spraying isocynate based finisher, wear approved respirator/clean air breathing apparatus

and cover exposed skin with latex gloves and an impervious hooded coverall.

Remove ill-fitting clothing. Remove ties, watches, rings and other loose jewellery and tie

back long hair.

Keep children and unauthorised persons away from the work area.

When not in use, ensure that the air supply is turned off.

Avoid unintentional operation of the spray gun.

When not in use, disconnect the spray gun from the air supply, clean thoroughly and store

safely.

Denotes risk of personal injury, loss of life or damage to the tool

in case of non-observance of the instructions in this manual.

Wear hearing protection.

Wear safety goggles.

Contact with or inhalation of dust coming free during use (e.g.

lead-painted surfaces, wood and metal) can endanger your

health and the health of bystanders. Always wear appropriate

protective equipment, such as a dust mask. Always use proper

dust extraction during use.

Wear gloves.