11

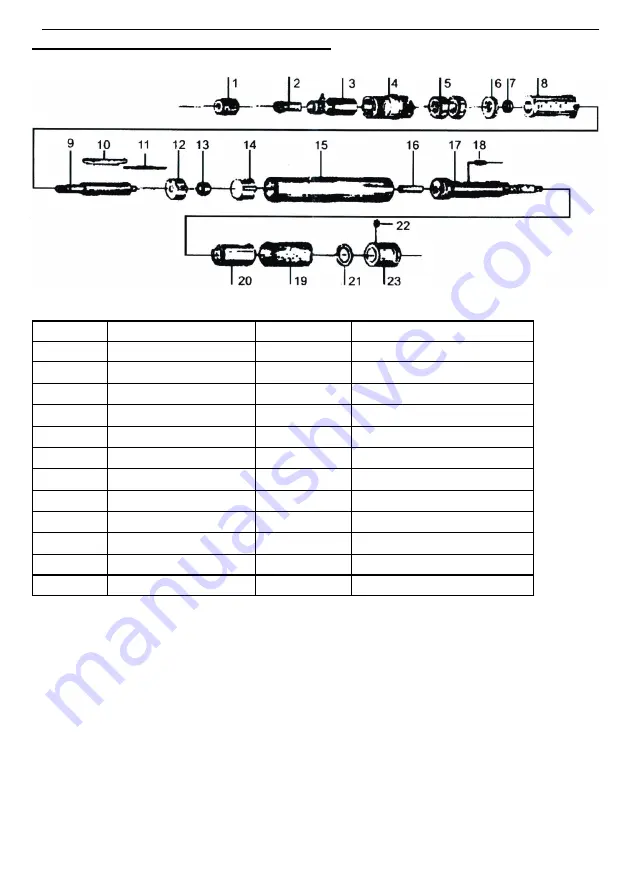

ASSEMBLY DIAGRAM AND PARTS LIST

INDEX NO. DESCRIPTION

INDEX NO.

DESCRIRTION

1

CLAMPING NUT

13

BALL BEARING

2

COLLET

14

INTAKE PLATE

3

FRONTCOVER

15

SLEEVE

4

COLLET FONDATION

16

INTAKE STEELTUBE

5

BALLBEARING

17

HOSE PLUG

6

SPACER

18

PIN

7

LATERAL DISC

19

SLIDING KNOB

8

CYLINDER

20

0 RING

9

ROTOR

21

0 RING

10

FIBRE VANES

22

SCREW

11

PIN

23

REAR END HOLDER

12

BEARING PLATE