6

6. Grip the tool as lightly as possible (while still maintaining a secure hold). Let the tool do

the work.

7. To reduce vibration, maintain tool as explained in this manual. If abnormal vibration

occurs, stop immediately.

SPECIFICATIONS

Maximum air pressure: 90psi

Free speed: 54,000rpm

Collet size: 1/8" or 3mm

Air inlet:1/4"

Average air consumption: 2cfm

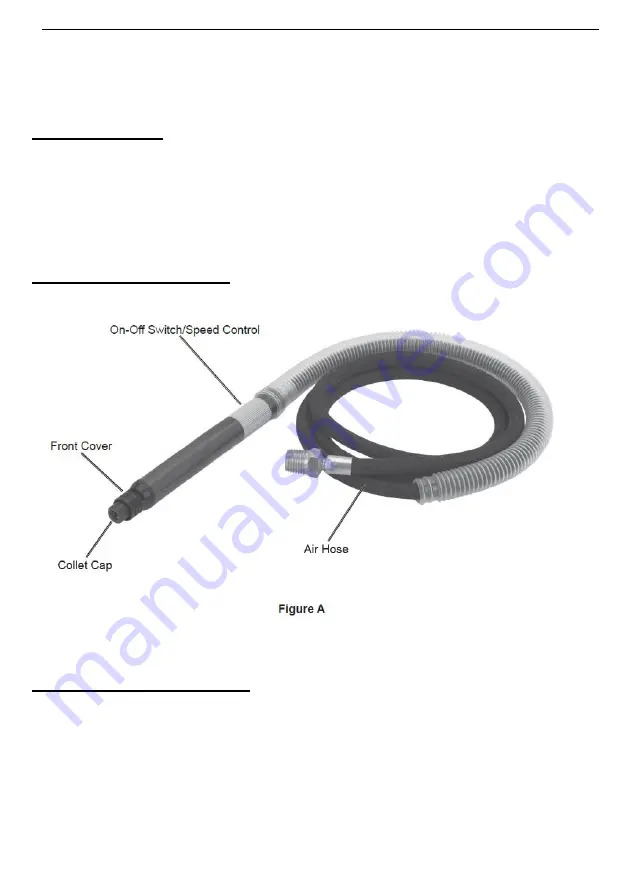

Components and Controls

INITIAL SETUP & ASSEMBLY

Air Supply

WARNING:

To prevent serious injury from explosion, use only clean, dry, regulated,

compressed air to power this tool. Do not use oxygen, carbon dioxide, combustible gases,

or any other bottled gas as a power source for this tool.

1. Incorporate a filter, regulator with pressure gauge, oiler, in-line shutoff valve, and quick

coupler for best service. Refer to the diagram at the end of this manual for more information.

An in-line shut-off ball valve is an important safety device because it controls the air supply