9

7. TROUBLESHOOTING

Problem

Possible Causes

Suggested Remedy

Spray size generally uneven

due to poor atomization.

1.Too much paint entering air

flow.

2. Insufficient air hitting paint

flow.

1.Decrease paint flow or reduce the nozzle to

the next size down.

2.Increase air flow on the spray gun's air control.

Intermittent spray.

1. Air is getting into the paint

circuit.

1.Tighten the nozzle up with the multi size

spanner.

2.Check the paint pot is not empty.

A lot of overspray.

1.Spray gun distance from

work piece.

2.Technique.

3. Atomization too high.

1. Maintain a distance of approx. 20cm.

2. Make sure you are not flicking the gun on the

leading or trailing edge.

3. Reduce air flow on the spray gun's air control.

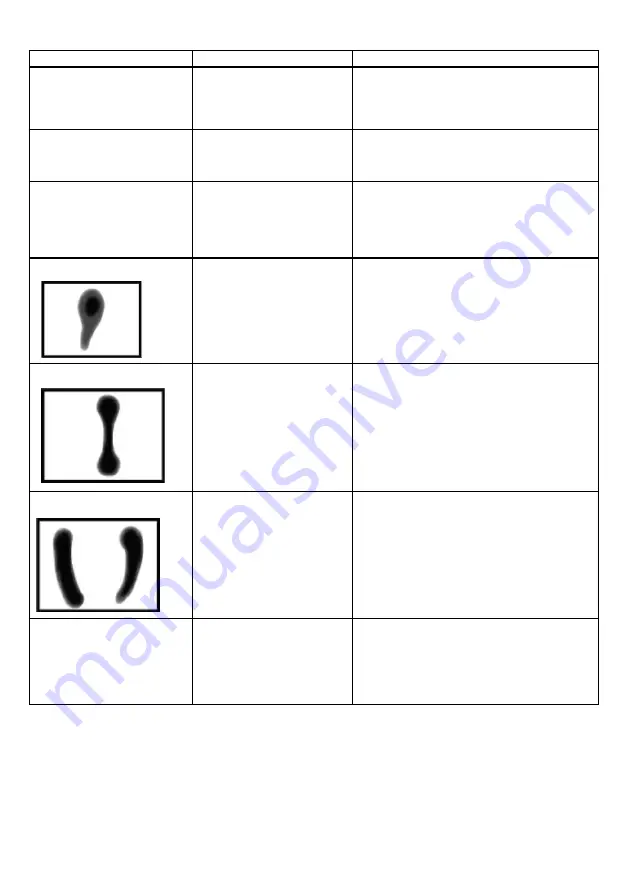

Badly formed spray pattern.

1. Nozzle or air cap alignment.

2. Debris or dried paint

blocking air cap or nozzle.

3. Needle tip worn or damage.

1. Check that both are correctly seated.

2. Check and if necessary clean the air cap and

nozzle.

3. Replace needle assembly.

Lack of spray in the centre.

1.Not enough paint entering air

flow.

2.Too much air flow.

1. Increase paint flow or step up the

nozz\e to the next size.

2. Reduce air flow on the spray gun's

air control.

Uneven fan shape.

1. Air cap holes blocked on

one side.

2. Needle tip and air cap worn

or damaged nozzle.

1. Clean the air cap thoroughly.

2. Replace needle assembly.

Air or paint leaking.

1. Sticking trigger or needle

mechanism.

2. Loose or worn packing

washers.

1. Lubricate all moving parts,

2. Check tightness. If tight, repla

lubricate packing washers.

NOTE:

Any adjustments made to remedy a problem will alter the original test pattern results. Slight rebalancing

may be necessary.