inspection, Maintenance, and cleaning

warning! Make sure the Throttle Lever (20) is in its “OFF” position and that

the Air Punch/Flange Tool is disconnected from its air supply before performing any

inspection, maintenance, or cleaning procedures.

before each use, inspect the general condition of the tool. Check for loose

screws, misalignment or binding of moving parts, cracked or broken parts, and

any other condition that may affect its safe operation. If abnormal noise or vibra-

tion occurs, have the problem corrected before further use.

do not use damaged

equipment.

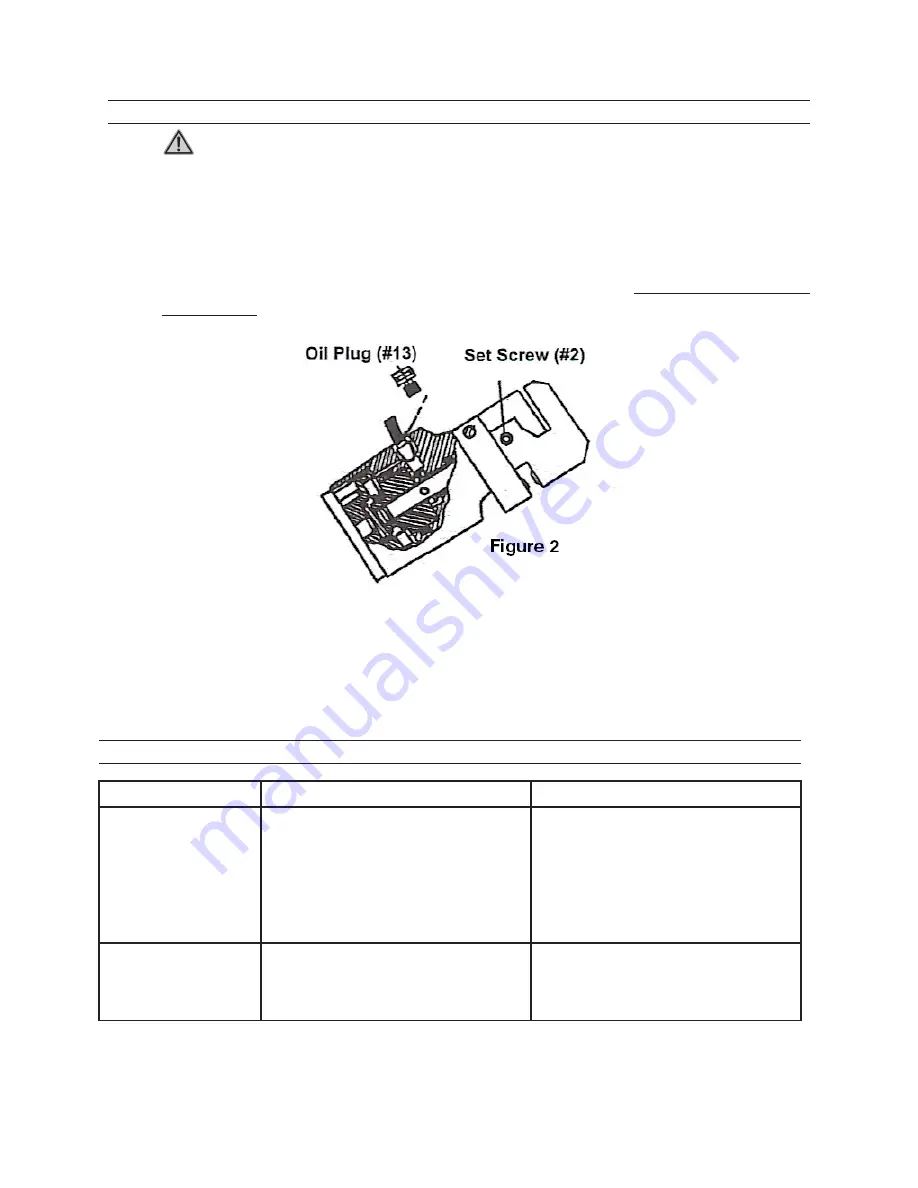

when necessary, fill the hydraulic system with a high quality hydraulic oil. Re-

move the Oil Plug (13), refill and then replace the Oil Plug (13). See

figure 2

To adjust the Punch, loosen the Set Screw (2) and rotate the tool head. After mak-

ing needed adjustment, tighten the Set Screw (2). See

figure 2

1.

2.

3.

troubleshooting

problem

possible causes

probable solutions

Punch/Flange will not

start

Air supply not connected.

Air hose/hoses not securely

connected, or damaged and

leaking air.

1.

2.

Check, make sure air supply is

properly connected to the tool.

Check all air hose and connections.

if any air hose damage is found,

replace the damaged hose/hoses.

Do not apply duct tape or wraps of

any kind to the damaged area.

1.

2.

Punch/Flange will

not operate smoothly

when punching and/or

flanging.

Possible dirt or debris gathered in

moving parts.

1.

Make sure Anvil (9) and Clamp (1)

as well as the Punch Die (3) and

Punch (6) are wiped clean of any

dirt or debris.