Disassembly Guide

60

10. Install the seven screws in the Power Supply and tighten.

11. Connect the fan harness to J1 on the Power Supply.

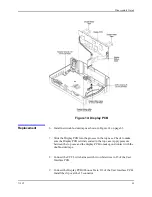

12. Install the PEM in the bottom case with the fuse drawer facing down. A

tab in the bottom case holds the PEM in place. Insert the bottom wing of

the PEM between the tab and the internal edge of the sidewall of the

bottom case. Push the PEM down and towards the outside of the monitor

until it clicks into place.

13. Complete the replacement procedure in paragraph

Monitor Assembly

on

Cooling Fan

Removal/

Replacement

Removal

1. Complete the procedure in paragraphs

Prior to Disassembly

on page 52,

and

Monitor Disassembly

on page 53.

2. Disconnect the fan wire harness from J1 on the Power Supply PCB (see

3. Lift the cooling fan from the slots in the bottom case.

Summary of Contents for OXIMAX N-595

Page 1: ......

Page 8: ...This page intentionally left blank...

Page 13: ...Introduction N 595 5 Figure 4 Trend Softkey Map...

Page 50: ...This page intentionally left blank...

Page 76: ...This page intentionally left blank...

Page 82: ...This page intentionally left blank...

Page 96: ...This page intentionally left blank...

Page 98: ...Data Port Interface Protocol 90 Figure 19 Data Port Setup...

Page 116: ...This page intentionally left blank...

Page 125: ...Figure 27 Main PCB Schematic Diagram Sheet 1 of 13 117...

Page 126: ...Figure 28 Main PCB Schematic Diagram Sheet 2 of 13 119...

Page 127: ...Figure 29 Main PCB Schematic Diagram Sheet 3 of 13 121...

Page 128: ...Figure 30 Main PCB Schematic Diagram Sheet 4 of 13 123...

Page 129: ...Figure 31 Main PCB Schematic Diagram Sheet 5 of 13 125...

Page 130: ...Figure 32 Main PCB Schematic Diagram Sheet 6 of 13 127...

Page 131: ...Figure 33 Main PCB Schematic Diagram Sheet 7 of 13 129...

Page 132: ...Figure 34 Main PCB Schematic Diagram Sheet 8 of 13 131...

Page 133: ...Figure 35 Main PCB Schematic Diagram Sheet 9 of 13 133...

Page 134: ...Figure 36 Main PCB Schematic Diagram Sheet 10 of 13 135...

Page 135: ...Figure 37 Main PCB Schematic Diagram Sheet 11 of 13 137...

Page 136: ...Figure 38 Main PCB Schematic Diagram Sheet 12 of 13 139...

Page 137: ...Figure 39 Main PCB Schematic Diagram Sheet 13 of 13 141...

Page 138: ...Figure 40 Main PCB Assembly Drawing Front View 143...

Page 141: ...Figure 43 Linear Power Supply Assembly Drawing 149 AC FERRITE DC FERRITE...