STEP 6:

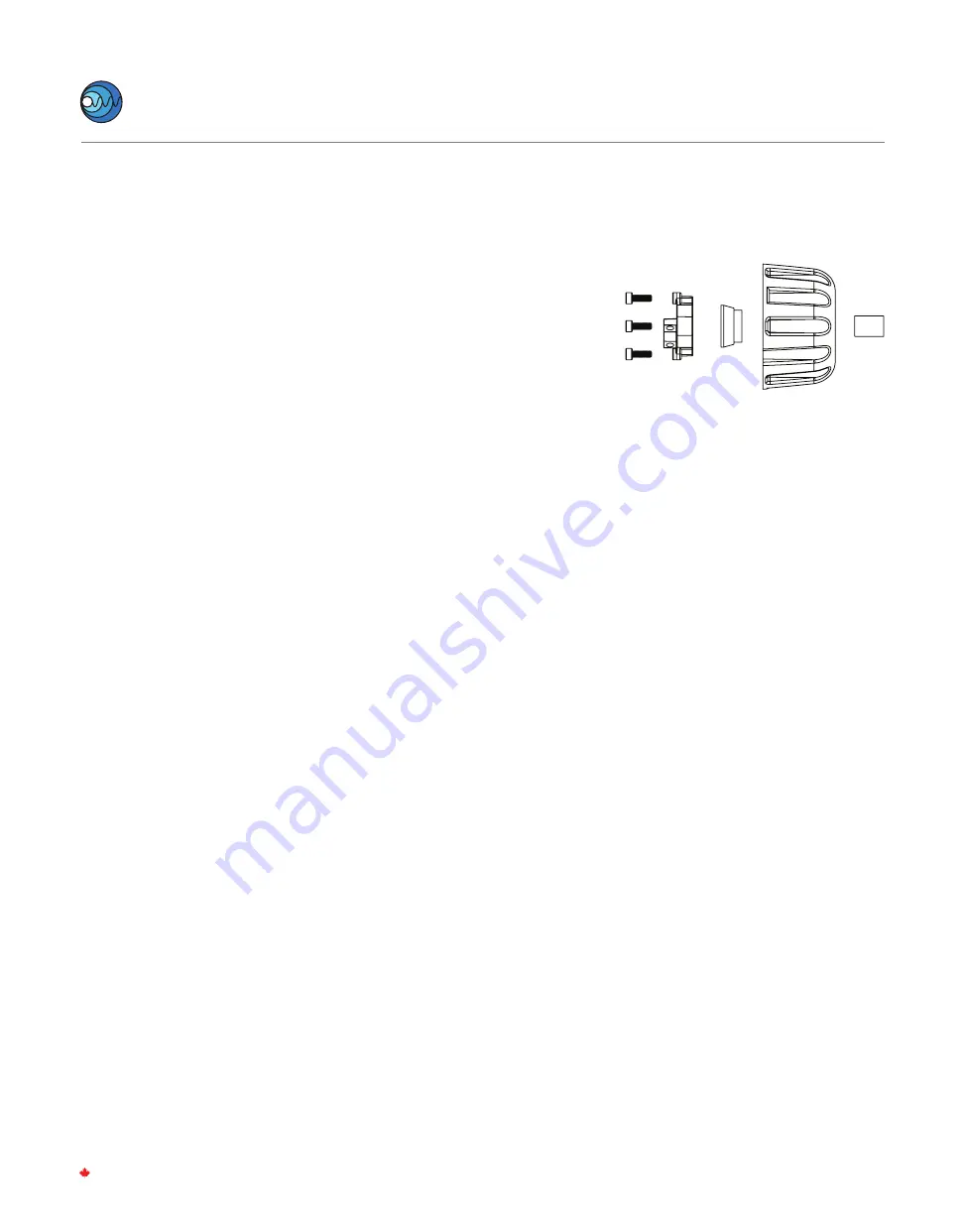

To Maintain ingress protection the final module must

have the blank end plugged. On the end module,

assemble the cord clamp and gland cap together using

two M4 fasteners and Torque to 20 in-lbs (2.3 N-m).

Install rubber Gland, Gland Cap assembly, and cylindri-

cal plug into the un-wired end-cap and torque M4

fasteners to 20 in-lbs (2.3 N-m) to secure in place and

compress gland seal around the cylindrical plug.

Attach End Cap Assembly to the core with the supplied

M4 socket head cap screws (3) with M4 hex driver

torque to 2.3 N-m (20 in-lbs).

STEP 7:

Attach mounting accessory if used (refer to Step 2 in LS

installation).

STEP 8:

Install suitable UL/CSA Listed or Recognized connector

for the environment and zone where the electrical

connection will be made or connect wiring lead to a

listed junction box suitable for the environment and

zone of use. Ordinary location plugs may be used only if

the electrical connection to power is made outside of

all hazardous environments or classified zones. Where

connections to electrical power will be made inside

hazardous classified zones, only UL/CSA Listed or

Recognized connectors rated for the environment,

Class/Division or Zone, temperature, and hazardous gas

or dust group present may be used.

STEP 9:

For raised installations, attach light stringer to fixed

infrastructure (handrail, exposed beams, pipe rack, etc.)

in desired location with adjustable strapping, hook, or

surface mount bracket accessories.

Cam buckle straps, stainless steel mounting clamps,

hook and surface mounts are available separately.

INSTALLATION (CONT.)

Step 6

TM

Nemalux

I N D U S T R I A L

LS Series

rev. A-20

5-6

www.nemalux.com | sales@nemalux.com | Tel 403•242•7475 | Fax 403•243•6190

MADE IN CANADA