3

NEMIC-LAMBDA

SWS

50

⋅

75

⋅

100

⋅

150

Series

INSTRUCTION MANUAL

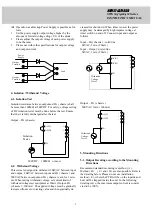

(B) Operation as a Backup Power Supply is possible as fol-

lows.

1.

Set the power supply output voltage higher by the

amount of forward voltage drop ( Vf ) of the diode.

2.

Please adjust the output voltage of each power supply

to be the same.

3.

Please use within the specifications for output voltage

and output current.

Output

Terminal

Output

Terminal

Load

Power

Supply

4. Isolation / Withstand Voltage

4-1. Isolation Test

Isolation resistance between output and FG ( chasis ) shall

be more than 100M

Ω

at 500VDC. For safety, voltage setting

of DC isolation tester must be done before the test. Ensure

that the it is fully discharged after the test.

Output ~ FG (chassis)

AC(L)

AC(N)

FG

+

+

-

-

Isolation

Tester

500VDC,

100M

Ω

or more

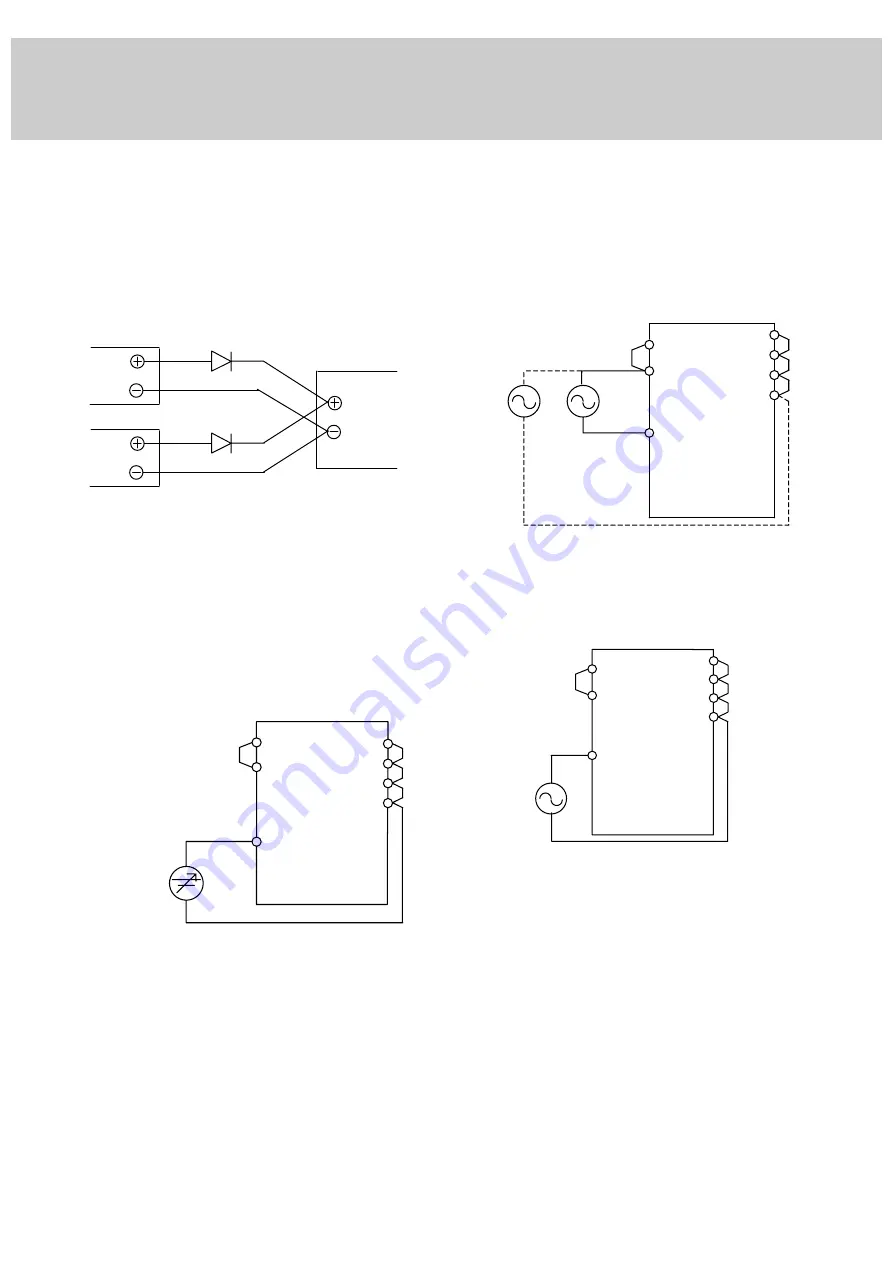

4-2. Withstand Voltage

This series is designed to withstand 3.0kVAC between input

and output, 2.0kVAC between input and FG ( chassis ) and

500VAC between output and FG ( chassis ) each for 1 min-

ute. When testing withstand voltage, set current limit of

withstand voltage test equipment at 20mA ( Output-FG

( chassis ) : 100mA ). The applied voltage must be gradually

increased from zero to testing value and then gradually de-

creased for shut down. When timer is used, the power

supply may be damaged by high impulse voltage at

timer switch on and off. Connect input and output as

follows.

Input ~ FG( chassis ) : solid line

2kVAC, 1min ( 20mA )

Input ~ Output : dotted line

3kVAC, 1min ( 20mA )

AC(L)

AC(N)

FG

+

+

-

-

Withstand

Voltage

Tester

Output ~ FG ( chassis )

500VAC, 1min ( 100mA )

AC(L)

AC(N)

FG

+

+

-

-

Withstand

Voltage

Tester

5. Mounting Directions

5-1. Output Derating according to the Mounting

Directions

Recommend standard mounting is method ( A ).

Method ( B ) ( C ) and ( D ) are also possible. Refer to

the derating below. Please do not use installation

method ( E ), where the PCB will be on the topside and

heat will be trapped inside the unit. In the following

derating curve, the maximum output current is consid-

ered to be 100%.