6.5 RESISTIVE PROGRAMMING OF OUTPUT VOLTAGE AND CURRENT LIMIT

For resistive programming, internal current sources, for output voltage and/or output current control,

supply 1mAcurrent through external programming resistors connected between J1-9 & 22 and J1-10

& 23. The voltage across the programming resistors is used as a programming voltage for the power

supply. Resistance of 0~5Kohm or 0~10Kohm can be selected to program the output voltage and

current limit from zero to full scale.

A variable resistor can control the output over its entire range, or a combination of variable resistor

and series/parallel resistors can control the output over restricted portion of its range.

Perform the following procedure to set the power supply to Resistive programming:

1. Turn the AC On/Off switch to Off.

2. Set setup switch SW1-1 to its UP position for output voltage external programming and

SW1-2 to its UP position for Output Current limit external programming.

3. Set SW1 position 3 to select programming resistor range according to Table 6-4.

4. Set SW1-7 to its UP position for output voltage resistive programming and

SW1-8 to its UP position for Output Current limit resistive programming.

5. Connect a short between J1-8 and J1-12 (refer to Table 4-4).

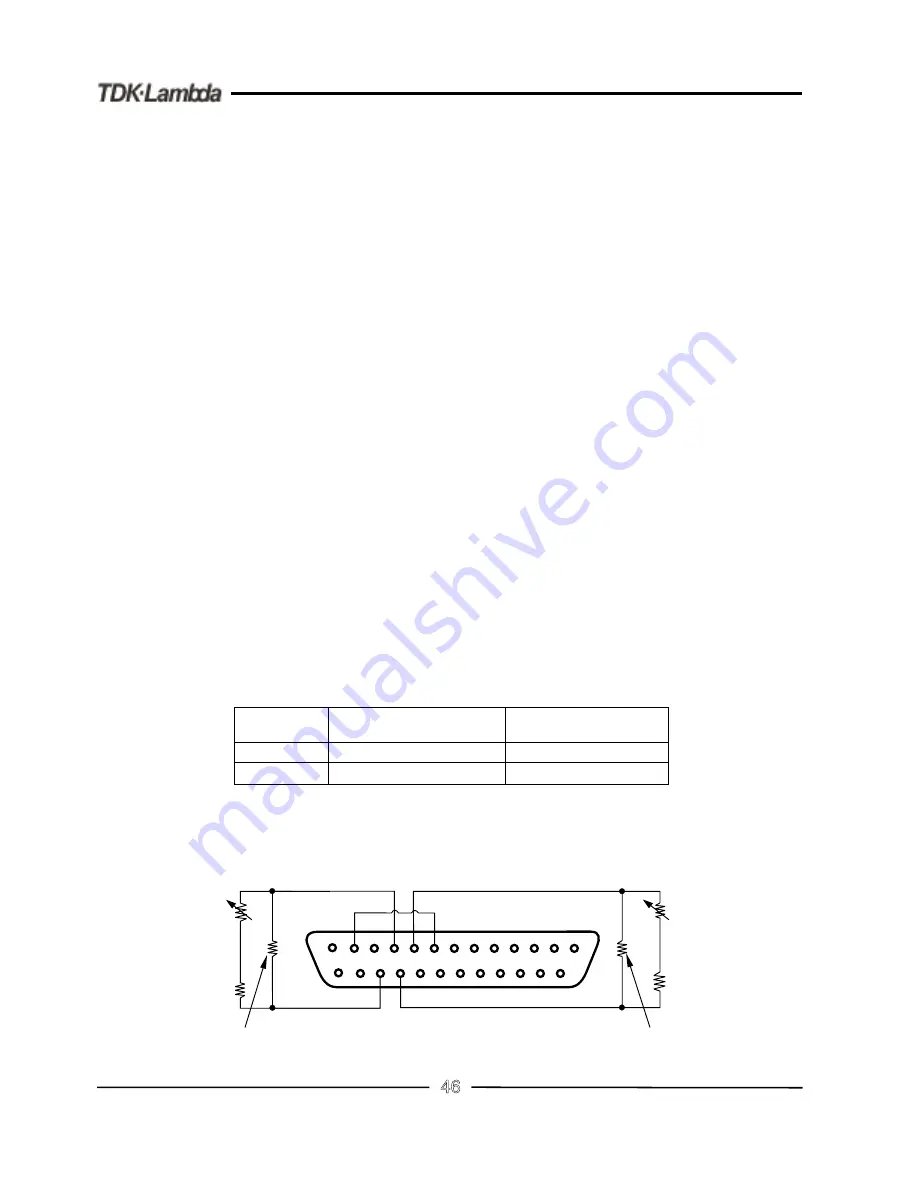

6. Connect the programming resistors to the mating plug of J1 as shown in Fig.6-2.

7. Set the programming resistors to the desired resistance and turn the power supply ON.

Adjust the resistors to change the power supply output.

1. SW1 positions 4, 5, 6 and 9 are not required for remote programming. Their setting can be

determined according to the application requirements.

2. The control circuits allow the user to set the output voltage and current limit up to 5% over

the model-rated maximum value. The power supply will operate within the extended range,

however it is not recommended to operate the power supply over its voltage and current

rating and performance is not guaranteed.

3. To maintain the temperature stability specification of the power supply, the resistors used for

programming should be stable and low noise resistors, with temperature coefficient of less

than 50ppm.

4. When resistive programming is used, front panel and computer control (via serial communication

port) of output voltage and current are disabled.

NOTES:

SW1-3 setting

UP

DOWN

Output Voltage programming

VPGM (J1-9)

0-10Kohm

0-5Kohm

Current limit programming

IPGM (J1-10)

0-10Kohm

0-5Kohm

Table 6-4: SW1-3 setting and programming range

46

1

14

13

25

10

9

23

22

CURRENT LIMIT

PROGRAMMING

OUTPUT VOLTAGE

PROGRAMMING

J1 connector, rear panel view

Fig.6-2: Remote resistive programming

PROGRAMMING

RESISTOR

PROGRAMMING

RESISTOR

OPTIONAL SETS

LOWER LIMIT

OPTIONAL SETS

LOWER LIMIT

OPTIONAL SETS

UPPER LIMIT

OPTIONAL SETS

UPPER LIMIT

12

8

Summary of Contents for TDK-Lambda Genesys GEN100-15

Page 2: ...This page intentionaly left blank ...

Page 6: ...This page intentionaly left blank ...

Page 74: ...NOTS ...