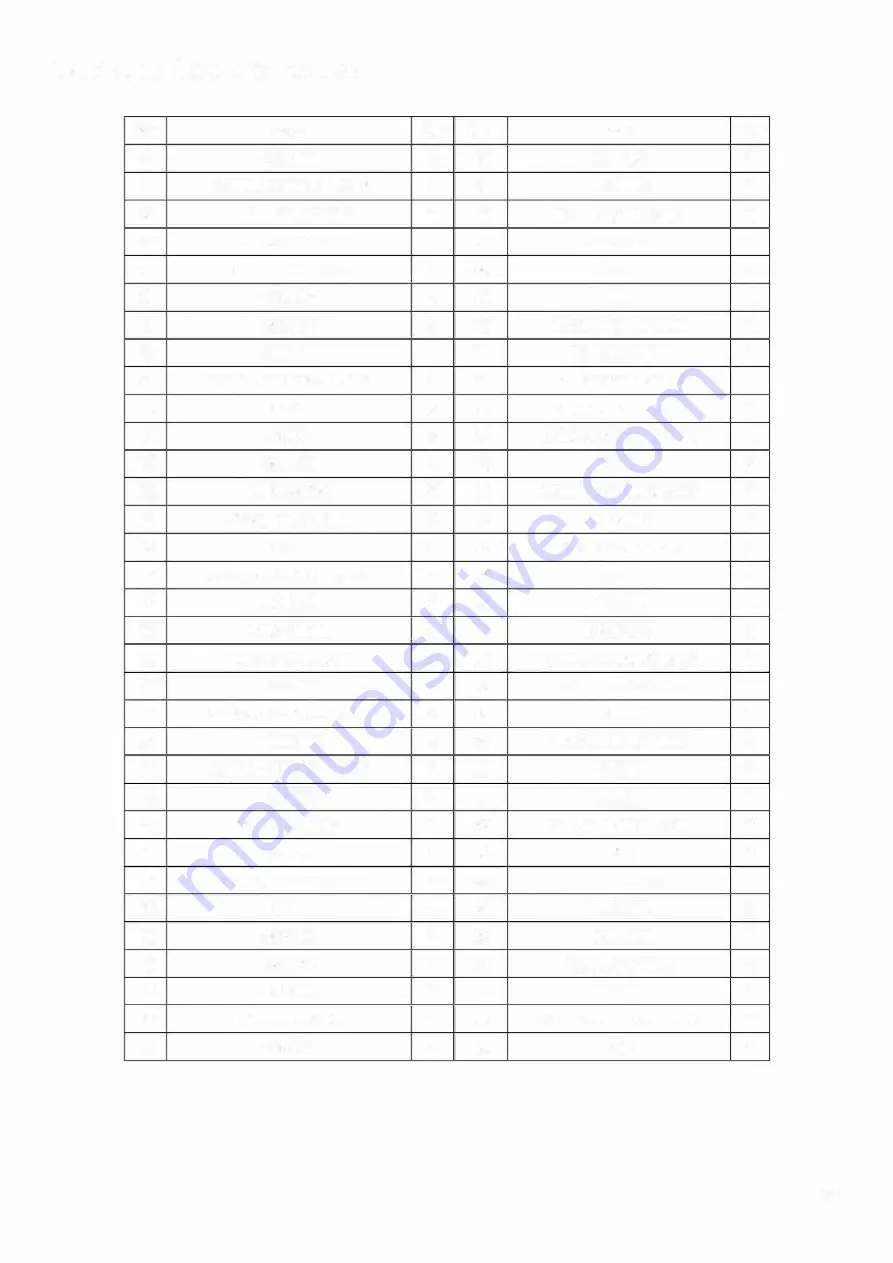

Table of Components

No.

Parts

Q'ty

No.

Parts

Q'ty

1

SCREW

1

34

0-RING

1

2

COMPRESSION SPRING

1

35

BUSHING

1

3

RELIEF VALVE PIN

1

36

MOTOR & GEAR SET

1

4

RELIEF DEVICE

1

37

BLOCKER

2

5

RELIEF VAL VE TOP

1

38

SCREW

2

6

0-RING

1

39

PIN

1

7

SCREW

2

40

TORSIONAL SPRING

1

8

CYLINDER

1

41

RELEASE LEVER

1

9

COMPRESSION SPRING

2

42

RELEASE TRIGGER

1

10

BALL

3

43

ADVANCE TRIGGER

1

11

0-RING

2

44

COMPRESSION SPRING

1

12

SCREW

2

45

SCREW

5

13

OIL SCREEN

2

46

COMPRESSION SPRING

1

14

PUSH IN FASTNER

2

47

HOUSING

1

15

BALL

2

48

SPRING WASHER

2

16

COMPRESSION SPRING

2

49

SCREW

2

17

SCREW

2

50

PISTON

1

18

DUST SEAL

2

51

DUST SEAL

1

19

BACK-UP RING

2

52

COMPRESSION SPRING

1

20

SCREW

2

53

CYLINDER COVER

1

21

COMPRESSION SPRING

2

54

SCREW

1

22

PLUNGER

2

55

TORSIONAL SPRING

2

23

COMPRESSION SPRING

1

56

YOKE

1

24

0-RING

2

57

LATCH

1

25

BACK-UP RING

1

58

DIE SIZING LOCK PIN

1

26

SCREW

1

59

PIN

1

27

RELEASE VALVE STEM

1

60

DIE HOLDER

1

28

BALL

1

61

HINGE PIN

2

29

SCREW

1

62

CRESENT

4

30

0-RING

1

63

BALL PLUNGER

4

31

SCREW

1

64

SCREW

1

32

OIL RESERVOIR

1

65

COMPORESSION SPRING

1

33

0-RING

1

66

PCB

1

17