6

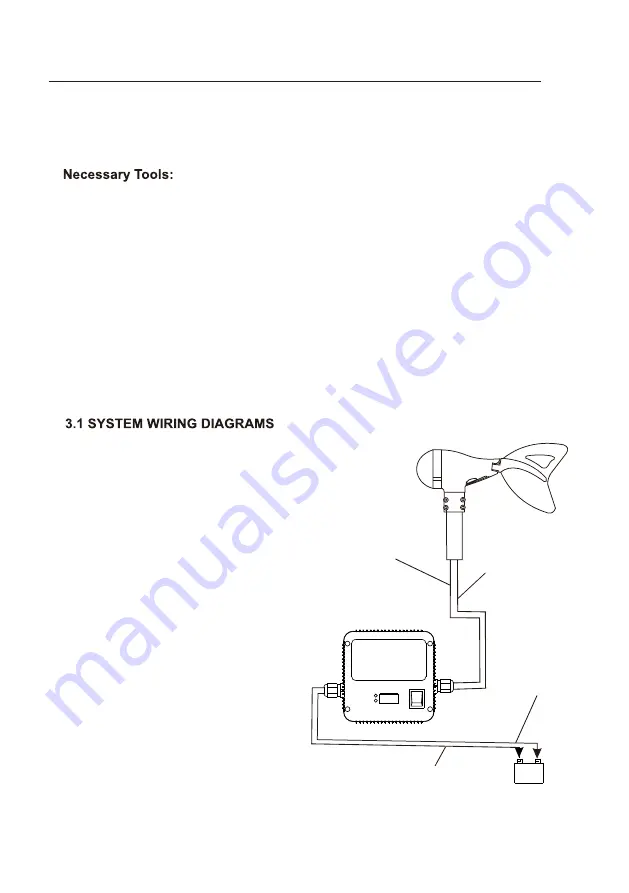

3. WIRING AND INSTALLATION PROCEDURES

Your Wind Turbine is shipped partially assembled. Please completely read

all procedures before beginning installation. NOTE: Do not install the blade/hub

until the turbine is mounted on the tower

4mm hex key wrench (included)

5mm hex key wrench (included)

8mm hex key wrench (included)

Power cables (not included):

#12 AWG (American Wire Gage) stranded.

Batteries (not included)

Steel Pipe: 1 1/2", Schedule 40 steel pipe (Actual OD 1.875 inches, 48mm) (not

included)

Torque wrench with 4mm, 5mm, and 8mm hex drives (not included)

Soldering iron or propane torch (not included)

Rosin core solder (not included)

Electrical tape or 1/4” (6-7mm) heat shrink (not included)

Wire strippers (not included)

Wire crimpers (not included)

NOTE: Do not connect to the battery.

Precheck

Spin rotor shaft slowly with your fingers

while at the same time connecting and

disconnecting the DC OUTPUT's positive

and negative wires. With the wires

connected, the rotor shaft should become

more difficult to rotate. With the wires

disconnected, it should spin freely.

Every time connect the DC

OUTPUT's wires (RED= Positive,

BLACK = Negative)

directly to the set of posts of the

Power Meter box, the controller LED will

lighten to indicate that the

controller is running properly.

CAUTION: DO NOT CONNECT WIND

GENERATOR POSITIVE TO BATTERY

NEGATIVE AND POWER METER BOX

NEGATIVE TO BATTERY POSITIVE FOR

EVEN A SECOND, OR ELSE WILL DAMAGE THE WIND GENERATOR'S

CONTROLLER AND VOID YOUR WARRANTY.

Red wire

Red wire

black wire

Black wire

Power Meter Box