Operation

Use different sprayheads for different part shapes. Select the appropriate

nozzle for the parts being coated.

_

Pinpoint nozzles for penetration

_

Eight-orifice nozzles for flat surfaces

_

Cylindrical nozzles for general purpose coating

Angle the nozzles to meet and follow the parts as they move through the

booth. Typical nozzle-to-part distance is 32,5 cm. Coat the

inside surfaces and recessed areas first, then coat the outside surfaces and

open areas.

Daily Maintenance

WARNING:

Make sure the spray gun is grounded before spraying powder

or cleaning the spray gun with compressed air. Without a ground

connection the spray gun will become electrostatically charged. Personnel

touching the spray gun could receive a shock.

1. Remove the powder feed hose from the pump and the air tubing from

the pump and diffuser. Use air gun to clean the hose, diffuser, and charge

module with compressed air.

NOTE:

Never blow powder through the feed hose back into the pump.

Turn on the booth exhaust fan, disconnect the hose from the pump, and

blow out the hose from the pump end into the booth.

2. Remove the diffuser from the gun body. Disassemble the diffuser and

clean the parts with compressed air and a clean, soft cloth. Check the

powder contact parts for wear and replace worn parts.

3. Blow out the charge module and sprayheads. Disassemble and clean

the charge module. Check the powder contact parts for wear and

replace worn parts.

NOTE:

Never use a knife or other sharp object to clean plastic parts.

Powder will build up on scratches on the powder contact surfaces. The

powder particles can fuse on impact and clog the spray gun.

WARNING:

All electrically conductive equipment in the spray area must be

grounded. Ungrounded or poorly grounded equipment can store an

electrostatic charge which can give personnel a severe shock or arc and

cause a fire or explosion.

4. Make sure all conductive equipment in the spray area, including the

spray guns, are connected to a true earth ground. The resistance from

part to ground, through the hangers and conveyor, must not exceed one

megohm. For best results, the resistance should be less than 500

&

.

Troubleshooting

4-1

Summary of Contents for PTA07

Page 1: ...PTA07 Powder Spray Customer Product Manual Part Issued 12 10 ...

Page 10: ......

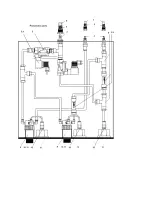

Page 16: ...PTAU07 Control module ...

Page 18: ...PTAU07 Control module ...

Page 19: ......