CHAPTER 3. OMNI DRIVE MODULE

3.4. ELECTRICAL INSTALLATION

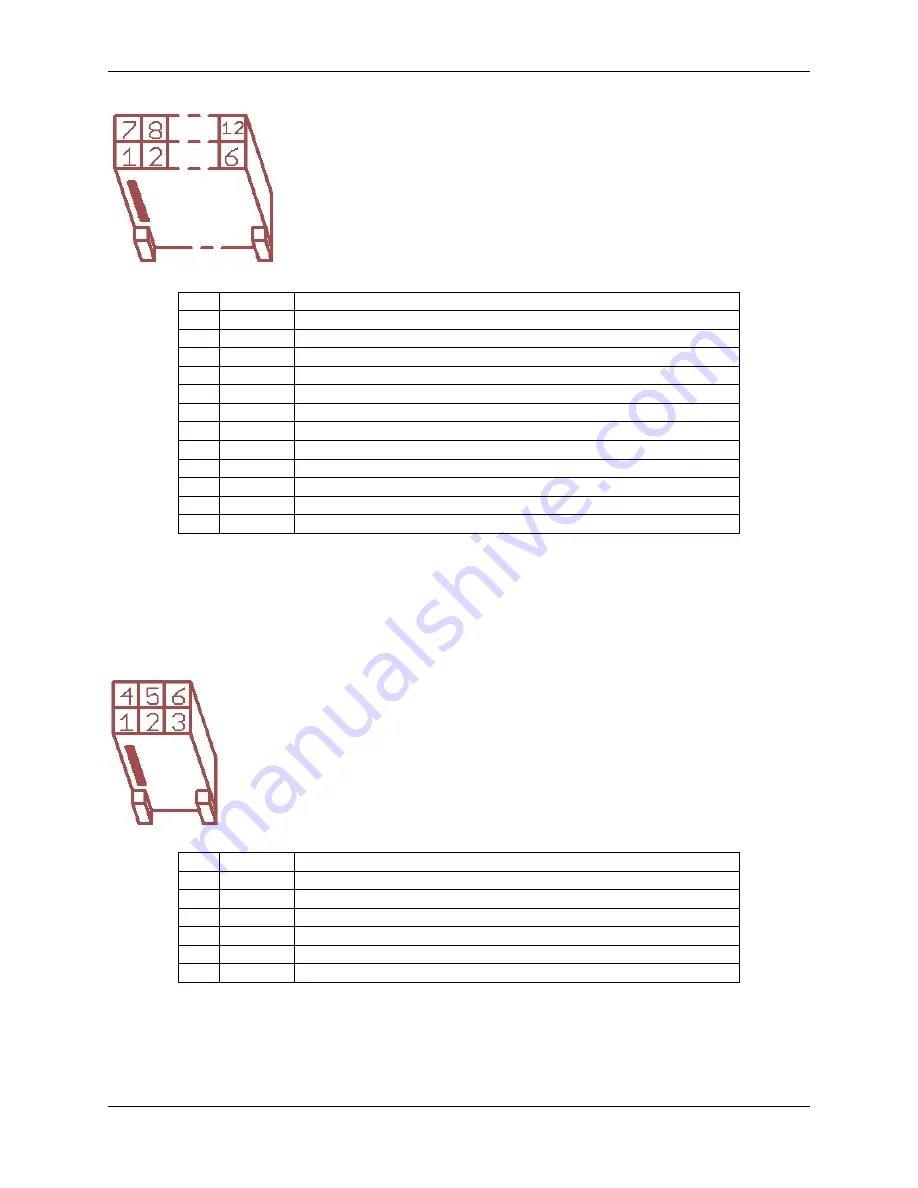

Pin

Function

Description

1

A+

Channel A of the TTL motor encoder, for motion monitoring

2

B+

Channel A of the TTL motor encoder, for motion monitoring

3

O-

Emitter contact of the optocoupler of digital output 1

4

G

Main ground

5

I-

Common ground of the digital inputs

6

I2

Digital input 2 (mind the limiting resistor)

7

A-

Channel A (inverted) of the TTL motor encoder, for motion monitoring

8

B-

Channel B (inverted) of the TTL motor encoder, for motion monitoring

9

O1

Collector contact of the optocoupler of digital output 1

10

VL

Logic supply (output)

11

I1

Digital input 1 (mind the limiting resistor)

12

I3

Digital input 3 (mind the limiting resistor)

3.4.3.1 Motion Monitoring

On request the connectors can be prepared to provide direct access to the encoder signals of the traction and / or

orientation motor from outside.

This option will change the pin assignment as follows.

Pin

Function

Description

1

O-

Emitter contact of the optocoupler of digital output 1

2

B+

Channel A of the TTL motor encoder, for motion monitoring

3

A+

Channel A of the TTL motor encoder, for motion monitoring

4

O1

Collector contact of the optocoupler of digital output 1

5

B-

Channel B (inverted) of the TTL motor encoder, for motion monitoring

6

A-

Channel A (inverted) of the TTL motor encoder, for motion monitoring

This option requires different connector housings:

TE Connectivity, HE14 receptacle double row 6 circuits, 281839-3

46