15

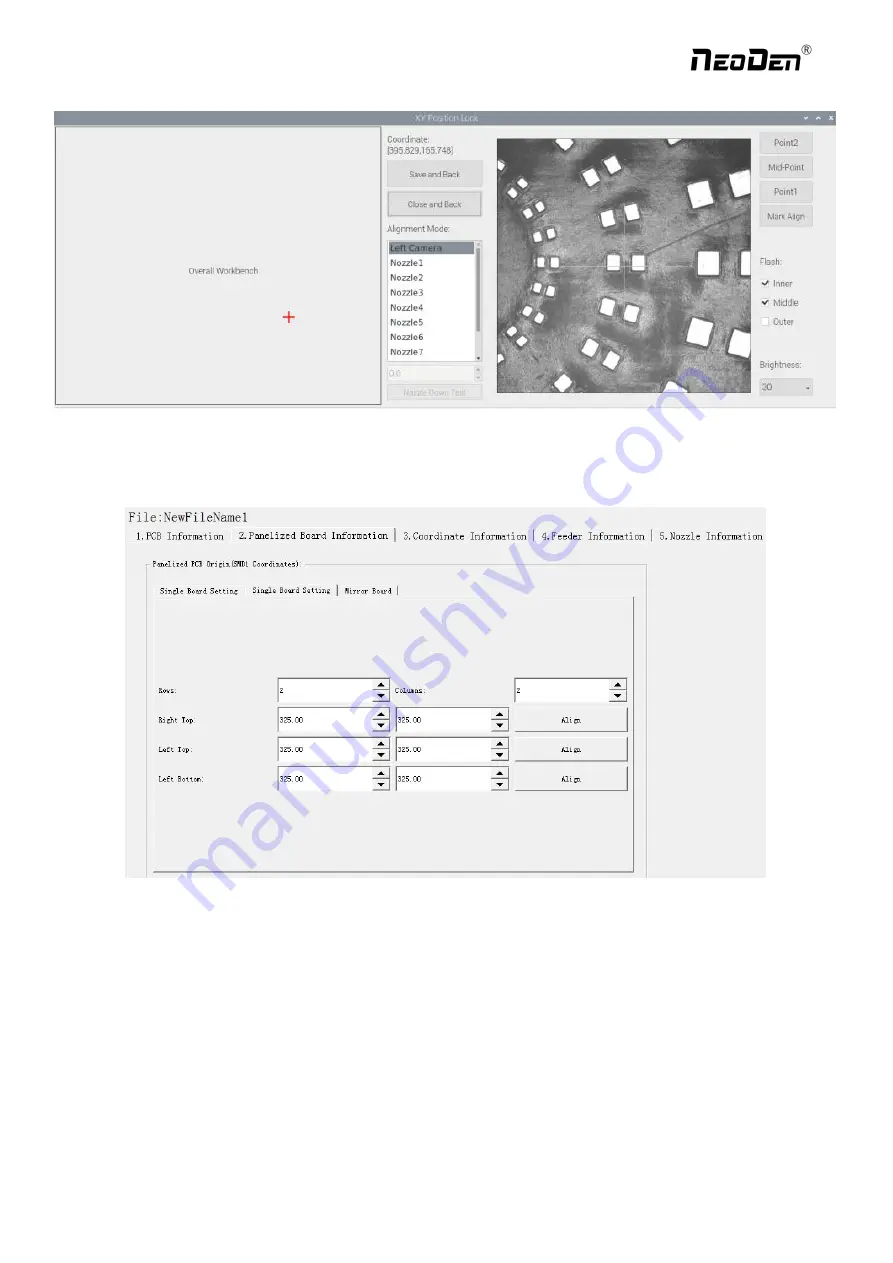

Click “ok”, it will back to the previous interface, click “create panelized list” button, the data which on the panelized list

will change.Can see the “SMD1 information”on the list and do double check via “align”button.

3.1.2

Panelized board

The steps of the panelized board programming are similar with the single board, but need pay some attention to several

points below

The row and column are determined by the positioning of PCB on working area. The direction along the rails is the column,

the direction perpendicular to the rail is row, then please enter data in the row and column.

Please refer to the data collecting method of each position information as following:

●

The data of “left bottom” is collected according to first component in the component list of programming file. Press

“align” of left bottom, find the left bottom panel that is nearest to the left side and nearest to the feeding position, then find

the first component which on the chip list of this panel, align the center of this component. After saving the data, it will

return to the “PCB information” automatically.

Zhejiang

NeoDen Technology Co.,Ltd.