32

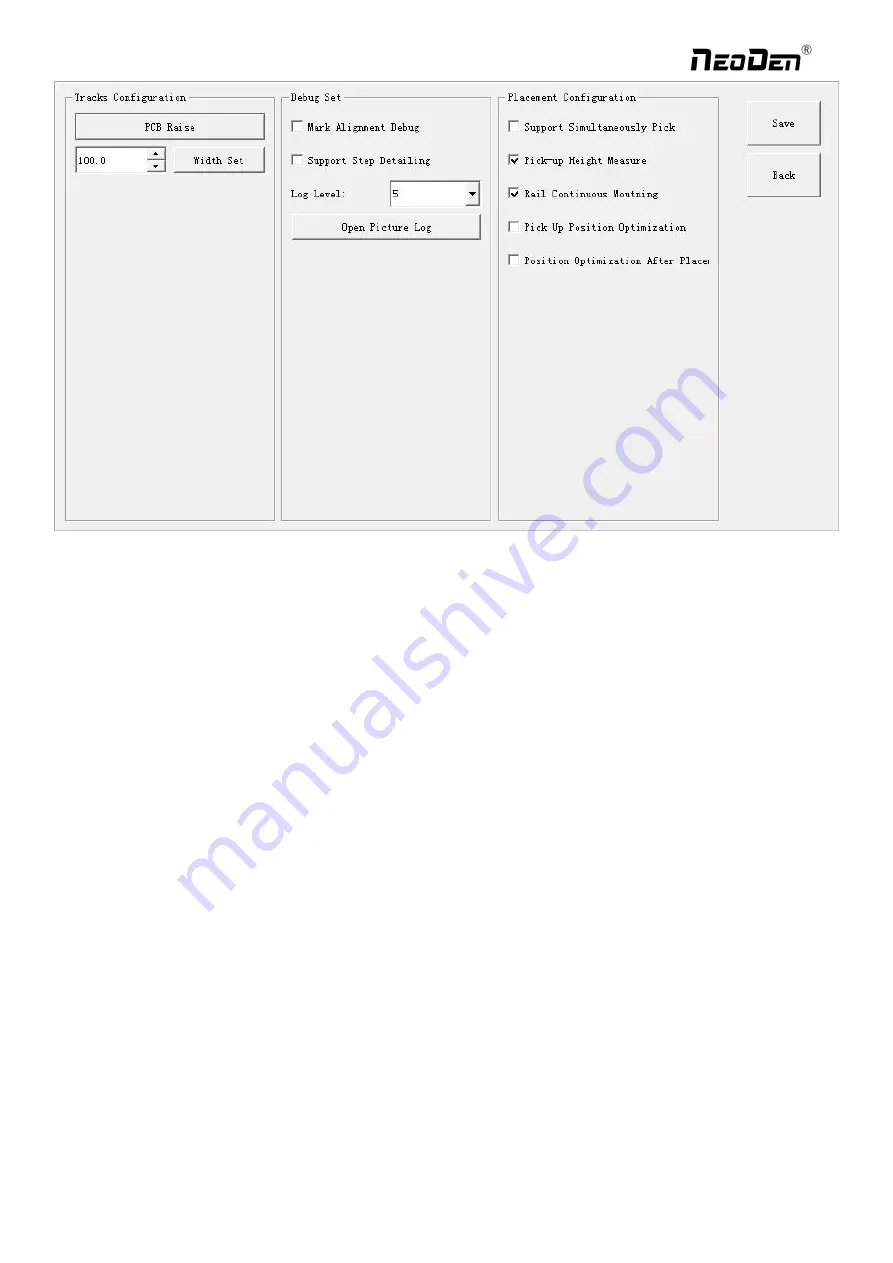

Tracks configuration: PCB Raise and Width Set are totally same as PCB Information interface.

Debug Set: details can be showed once you select the related item.

Support step detailing: once selected, every time you click “Step”, the machine will only execute one command.

This is

strongly recommended for the first assembly procedure.

Log level: the level sequence from low to high is from class1 to class5. Higher level, more information.

Open picture log: press this button, the file for stocking recognition photos will be opened from which recognition details

can be checked.

Placement configuration:

(

1

)

Support simultaneously pick: once selected, the nozzle head with same pick height can be downward to pick

components at the same time, it will greatly improve placement speed (

It is recommended for component size bigger

than 0603

).

(2) Rail continuous mounting: this is for PCB continuously feeding to realize automatic operation.

(3) Pick up position optimization: once selected this function, nozzle head can automatically optimize the pick position (

It

is recommended only for small components

).

(4) Position optimization after placement: If this function be selected in the first time, the position will be auto optimized in

future placement.

Exit: once assembly finished, please directly click this button and back to home interface.

File edit: If there’re many times of pick failure or big placement offset, which need to re-edit the file, please directly press

this button and it will directly turn to the file edit interface, after edit finished, save and back to the assembly interface will

be OK.

Zhejiang

NeoDen Technology Co.,Ltd.