7

6.2 Conveyor belt

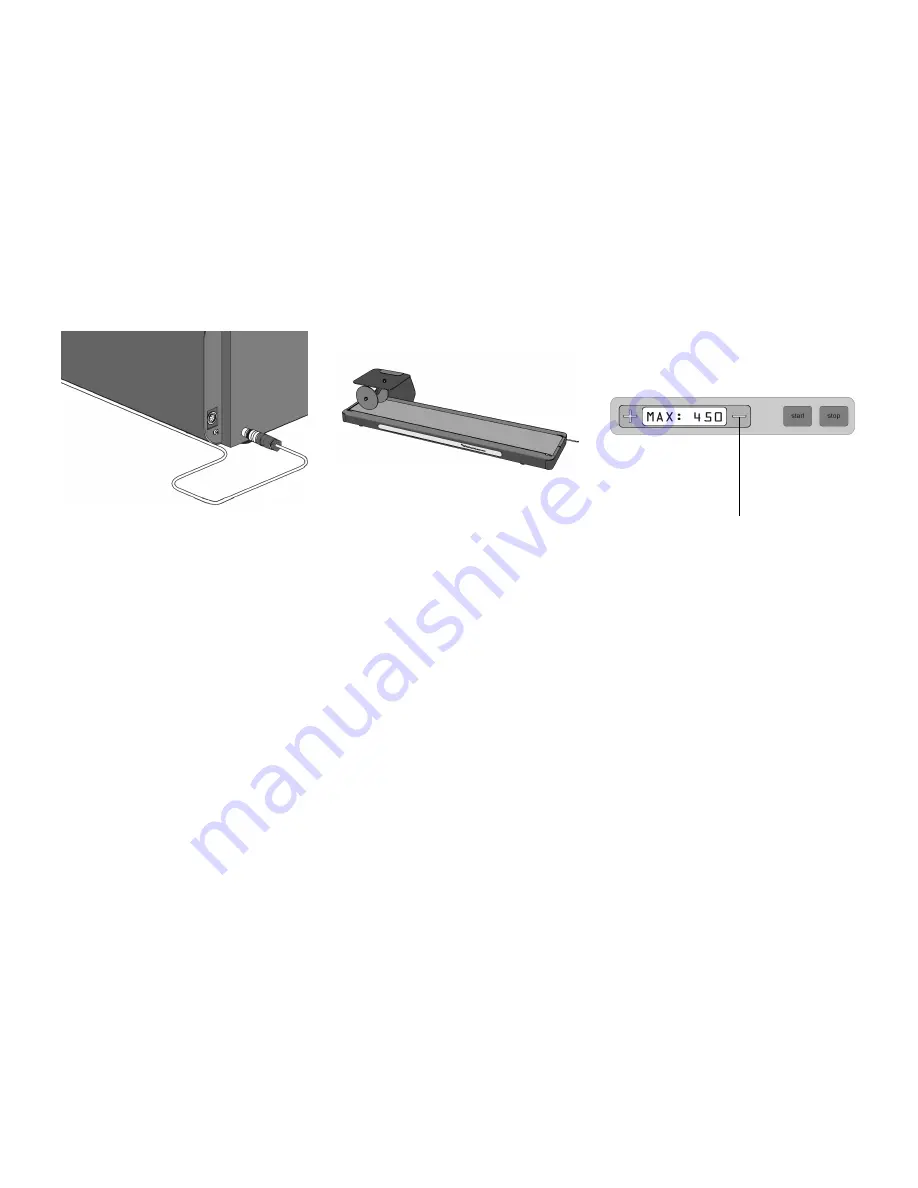

Instead of a receiving tray, a conveyor belt can be

connected (as shown in fig. 15). The mail can then be

processed by two or more persons. The conveyor

belt is connected to the socket at the back of the letter

opener as shown in figure 14.

After pressing “START” the conveyor belt will start

moving. The opened envelopes will be fed one after

another onto the belt. A sensor is located at the end

of the conveyor belt. This sensor will stop the machine

when the envelopes are not taken of the belt and

have reached the end of the belt. The moment the

documents are taken off the belt, the machine will

start processing again.

6.3 Two conveyor belts

It is possible to use two conveyor belts. This is

convenient when two or more persons are processing

the opened mail.

After pressing “START” the conveyor belts will start

moving. The opened envelopes will be fed one after

another onto the first belt. The sensor located at the

end of the last conveyor belt will stop the machine

when the envelopes are not taken of the belt and

have reached the end of the belt. The moment the

documents are taken of the belt, the machine will start

processing again.

When either a receiving tray with sensor or a conveyor

belt is used, an applicable job has to be selected first.

Fig. 14

Fig. 15

Fig. 16

6.4 Preset counter

The LO-1 can be equipped with a preset counter. The

machine stops when the preset number of envelopes to

be opened is reached.

The preset counter can only be altered when the machine

is in stop mode. After pressing the “-” key A for four

seconds the display will show “MAX: xxxx” as shown in

fig. 16. The number displayed is the last used value for

the preset counter. Then the preset counter can be

changed per digit. Select the digit by pressing the “start”

key. The respective digit will flash and can be altered by

pressing the “+” or the “-” key. By pressing the “stop”

key any changes are saved and the machines switches

back into “stop” mode.

If the preset counter is set to 0 (zero), the preset counter

is not used.

A

Summary of Contents for IM 30

Page 10: ...10 ...