N11

Hardware User Guide

Copyright © Neoway Technology Co., Ltd

11

⚫

Place low-ESR bypass capacitors close to the module to filter out high-frequency noise from the

power supply.

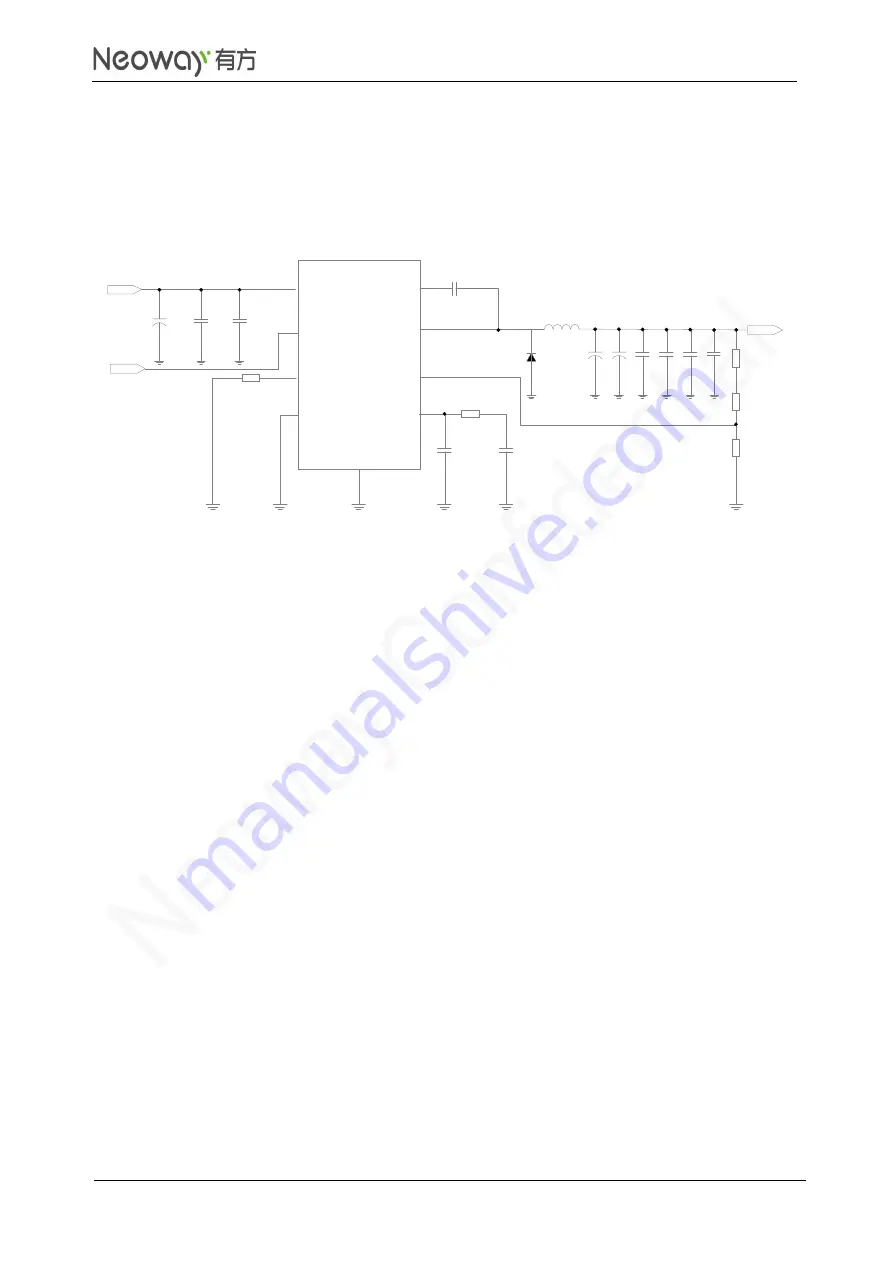

The following design is recommended for 5.5 V to 24 V input.

Figure 3-4

Recommended design 4

VIN

EN

RT/CLK

P-PAD

GND

BOOST

SW

FB

COMP

R1

47.5K

Ω

12K

Ω

100pF

0.01uF

L1

3.3uH

0.1uF

VBAT

470uF 100uF

22uF 0.1uF 100pF 33pF

1k

Ω

47.5k

Ω

12k

Ω

SS36

VIN

(4.5V-42V)

C1

100uF

C2

22uF

C3

0.1uF

TPS54340

D1

C4

C5

C6

C7

C8 C9 C10 C11 C12

R2

R3

R4

R5

PWR_EN

⚫

Select DC-DC that outputs a maximum current larger than 2 A when the output of power supply

is much larger than the permissible voltage across VBAT.

⚫

500 kHz or higher switching frequency is recommended for DC-DC.

⚫

The switching frequency of DC-DC might produce EMC noise and it determines the performance

of end products.

⚫

Add surge protection to the front end of the power supply circuit if automotive battery supplies

power. The maximum safe operating voltage of the component should be larger than 42 V.

⚫

Place TVS2 close to the input interface of the power supply to clamp the surge voltage before it

enters back-end circuits. Therefore, the back-end components and the module are protected.

⚫

Place C7 close to the module. A large bypass tantalum capacitor (220 μF or 100 μF) or

aluminum capacitor (470 μF or 1000 μF) is expected to reduce voltage drops during bursts. Its

maximum safe operating voltage should be larger than 1.5 times the voltage across the power

supply.

⚫

Place low-ESR bypass capacitors close to the module to filter out high-frequency noise from the

power supply.

PCB Layout Guidelines

⚫

TVS diodes dissipate the transient pulse power during a surge and have a short response time.

Place the TVS as close to the interface as possible to ensure that the surge voltage can be

clamped before the pulse is coupled to the neighbor traces.

⚫

Place filer capacitors close to the power pin of the module to filter out the high-frequency noise

from the power supply.