SK300-XL Steam Humidifier

9

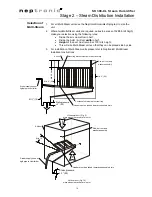

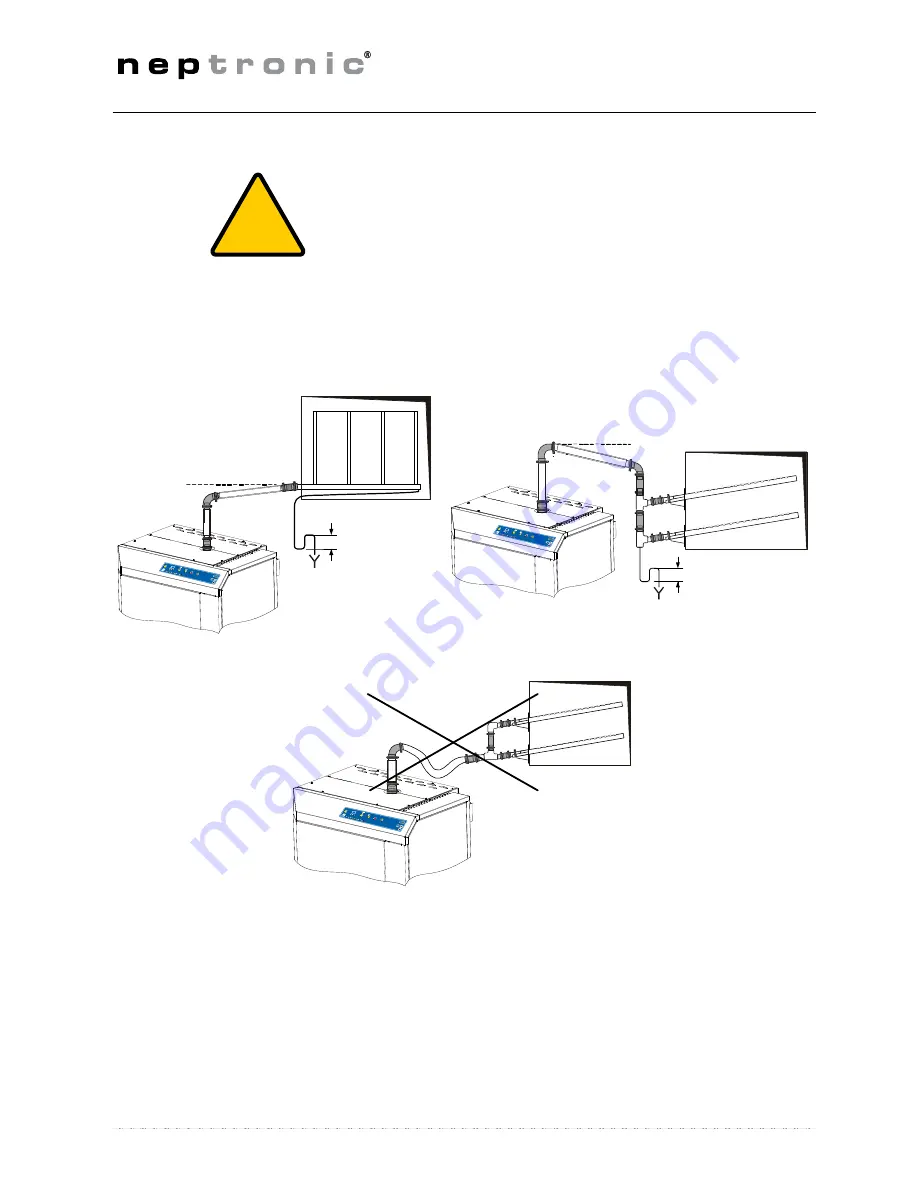

Stage 2 – Steam Distribution Installation

Fundamental Design

Concepts

1.

Maximum steam velocity in a pipe should not exceed 40 feet/sec

(12m/s) velocity. Velocities above this will generate noise.

2.

Minimum steam pipe gradient should be 7˚ i.e. 5’’ (125mm) rise in 40’’

(1m) run.

3.

The lowest point of any steam hose or rigid pipe must be the humidifier.

A steam separator (S trap) should be installed higher than the static

pressure of the system by at least 2’’ (50mm).

4.

Total length of the flexible steam hose should not exceed 16 feet (5 m)

or insulated rigid piping should not exceed 50 feet (15 m).

5.

Whenever possible use rigid copper piping, flexible steam hose can be

used for short runs or for interconnecting between rigid pipe runs, ensure

that there is no kink in the flexible hose.

When using rigid copper pipe, insulation should be used to diminish

condensation build up.

(Fig. 6)

dimensions in bracket are in mm

(Fig. 7)

dimensions in bracket are in mm

(Fig. 8)

6.

Connection pipe sizes between SK300-XL and steam distributor in the

duct should be 4 ¼’’ (108mm) up to 528lb/h (240kg/h)

7.

All Humidifiers above 220lb/h (100kg/h) capacity should use Multi-

Steam.

!

Min. 7°

Correct Installation

SK300-XL humidifier

with Multisteam.

Static pressure

+ 2'’ (50)

Min. 7°

Correct Installation

SK300-XL humidifier with 2 SAMB E2 manifolds

Static pressure

+ 2'’ (50)

Incorrect Installation