SK300-XL Steam Humidifier

25

Programming mode

To enter into programming mode, please push

button at any time, to advance the program function to the next

programming step in the menu push the same button twice.

Unless other instructions, you can make a selection by using

&

buttons on control panel.

Step Display

Description

Comment

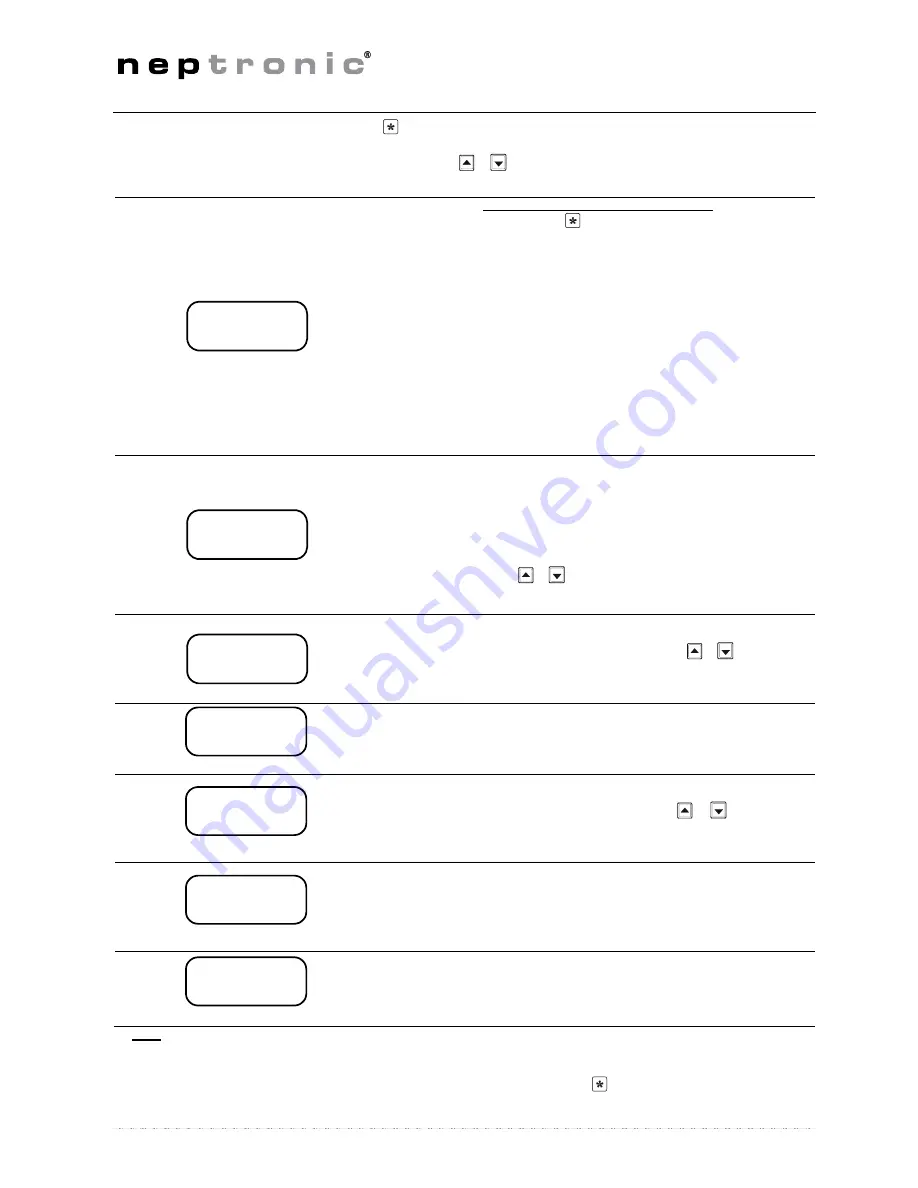

01

Set point RH origin

Out

: Output set point to

HRO20

Int

: Internal.

Value

: from 00 to 100%

Default: Out 30%

To enable set point to humidifier display

Press the

button to reach step 5, the RUNNING

message will appear.

Press and hold the TEST button located on Main Pc

board inside electrical compartment for 10 seconds.

Release the TEST button then press the RESET button

on the same main pc board. Set point is now displayed

on the humidifier display.

If Output is selected, the set point is sent from the humidifier

to the humidistat HRO20.

If SHR10 or SHC80 is connected with humidifier, please

select Internal, this will allow you to set up RH set point

directly from Humidifier.

To switch between Output and Internal Set point:

Press and hold the TEST button located on Main Pc

board inside electrical compartment until the change of

the value.

02

optional

Set point VAV allows Hi

limit Duct humidity control

OFF

: Duct humidity

control disable.

65%:

High limit Duct

humidity set point value.

Default: OFF

If Set point VAV is disabling, no humidity signal from the VAV

Duct will be considered. If a Set point VAV value is set, the

humidity output will be controlled by both space and High

limit duct humidity signal.

To allow Set point VAV value:

Press and hold the TEST button located on Main Pc board

inside electrical compartment until OFF is disappeared.

You can then select the VAV Set point value desired by

using

&

buttons on control panel.

Note: This Step will appear only if Internal has been selected at step

01

03

optional

Prop Band allows the set

up of proportional band.

From 3 to 9%

Default: 3%

Proportional band can be set from 3% to 9% of the humidity

set points values (Space and High limit duct).

Select the appropriate value by using

&

buttons on

control panel.

Note: This Step will appear only if Internal has been selected at step

01

04

D R A I N

8 H R S

Drain frequency.

From 1 to 24 hours

Default: 4 Hrs

Choose the initiation of a drain cycle for 1 to 24 hours.

In general, harder the water is, more often the drain cycle

should be.

Drain cycle setting does not affect the AFEC system.

05

R U N N I N G

0 6 4 5 H R S

Number of running hours

Information only, no

possible set up.

The humidifier has operated 645 hours since the last service.

After service, press simultaneously

&

buttons for 15

seconds to reset the number of hours of operation to zero.

This procedure will stop the CHECK indicator from flashing.

06

S E R V I C E

1 0 0 0 H R S

Hour span between

servicing.

From 400 to 1500

hours.

Default: 1000 Hrs

You can set the number of hours of operation before the

humidifier will call for service (blinking of CHECK light every

4 seconds) from 400 to 1500 hours.

In general, harder the water is, lower the number of hours of

operation before service should be.

07

L O C K O N

8 0 % P W R

Output Span.

From 00 to 100%.

Default: 100%

This option is available only on modulating model.

i.e.: In this case, the humidifier will deliver 80% of its

maximum rated output when at full demand.

Note:

Any changes made in the Program Mode are saved into a non-volatile memory.

When the humidifier is anywhere in the Menu Driven Program Mode, the normal operation of the humidifier is

halted.

To resume normal operation, exit the menu program mode by pressing the

button until the alphanumeric

display is clear. (This happens after step 7)

SETPOINT

OUT 30%

SETPOINT

VAV OFF

PROPBAND

3%