SK300-XL Steam Humidifier

26

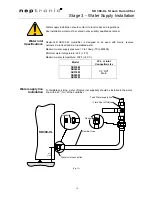

Control PC Board

Main Printed circuit board designated is common to all SK300-XL series humidifier, ON/OFF or modulating; this

pc board is equipped with an advanced microprocessor which controls all the humidifier functions.

The Printed circuit board which is directly connected onto the main pc board is installed only on modulating

model (suffix M).

Staging PC Board (HEC002SK) is controlling the 2 on/off stages (Contactor 2 and Contator3)

Main p.c. board

There are 3 water level L.E.D.’s in the upper right hand

side. They indicate the relative water height as sensed

by the water level sensor.

o

If HI is illuminated: water supply valve shuts off,

o

If LO is

off

: An evaporation chamber filling is ordered,

water supply valve opens

.

o

If

LA

is

off

: No water is detected by the water level

sensor, the power to the elements is shot off.

The 3 status L.E.D.’s at the center left side operate as

follows:

o

FILL indicates that the water supply valve is feeding

water.

o

DRAIN indicates the drain valve empties the

container.

o

CONT indicates that power is supplied to the

elements and the humidifier is producing steam.

TEST button should be used when commissioning the

humidifier; this will initiate a pre-programmed start-up

cycle. The start up cycle cleans the supply water and

the evaporation chamber (see section 1

1

– start-up).

This button enable also the set point control of the

humidistat to humidifier display (see section

9

.2 –

Programming) (this is available only on Modulating

model).

RESET button enable the bypass of start up sequence.

(Illus. 53)

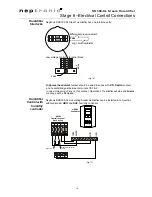

Modulating p.c. board

The 3 jumpers at the center of the p.c. board (Control Input) are used for proper selection of the incoming

control signal. See section Control signal set-up

The 3 jumpers at the bottom of the p.c. board (Humidity Input) are used for proper selection of the

incoming humidity signal. See section Humidity signal set up.

Staging p.c. board

This PCB does not require any set-up, it is connected to the contactor 2 and contactor 3 controlling the 2 on/off

stages.

PCB

970

81

9

RE

V

. C

TOP PCB

MODULATING

CONTROL

INPUT

HUMIDITY

INPUT

4-20mA

0-10V

2-10V

4-20mA

2-10V

0-10V