SKE Steam Humidifier

Installation Instructions and User Manual

7

3.

Mechanical installation

3.1.

General recommendations

CAUTION

: RISK OF ELECTRIC SHOCK. DISCONNECT THE APPLIANCE FROM THE ELECTRIC

SUPPLY BEFORE TO PROCEED TO INSTALLATION.

IMPORTANT

: Mechanical installation should conform to local codes and regulations.

Location: Plan a location easy to access in order to permit an easy inspection and servicing of the humidifier.

Do not install humidifier where failure of the appliance could cause damage to the building structure or to

costly equipment.

This location should be well ventilated; the ambient temperature should not exceed 30

C.

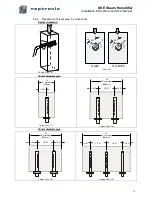

Typically, the total steam line length between the humidifier and the steam distributor depends on the steam

line material type:

For flexible steam hose: the total steam line length should not exceed 5 meters. For longer distances

use insulated hard piping.

For insulated hard piping: the total steam line length should be determined by the humidifier capacity:

0,67m for each kg/h capacity of the humidifier, with a maximum of 15 m. For longer steam line runs,

consult factory.

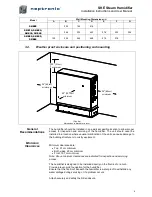

3.2.

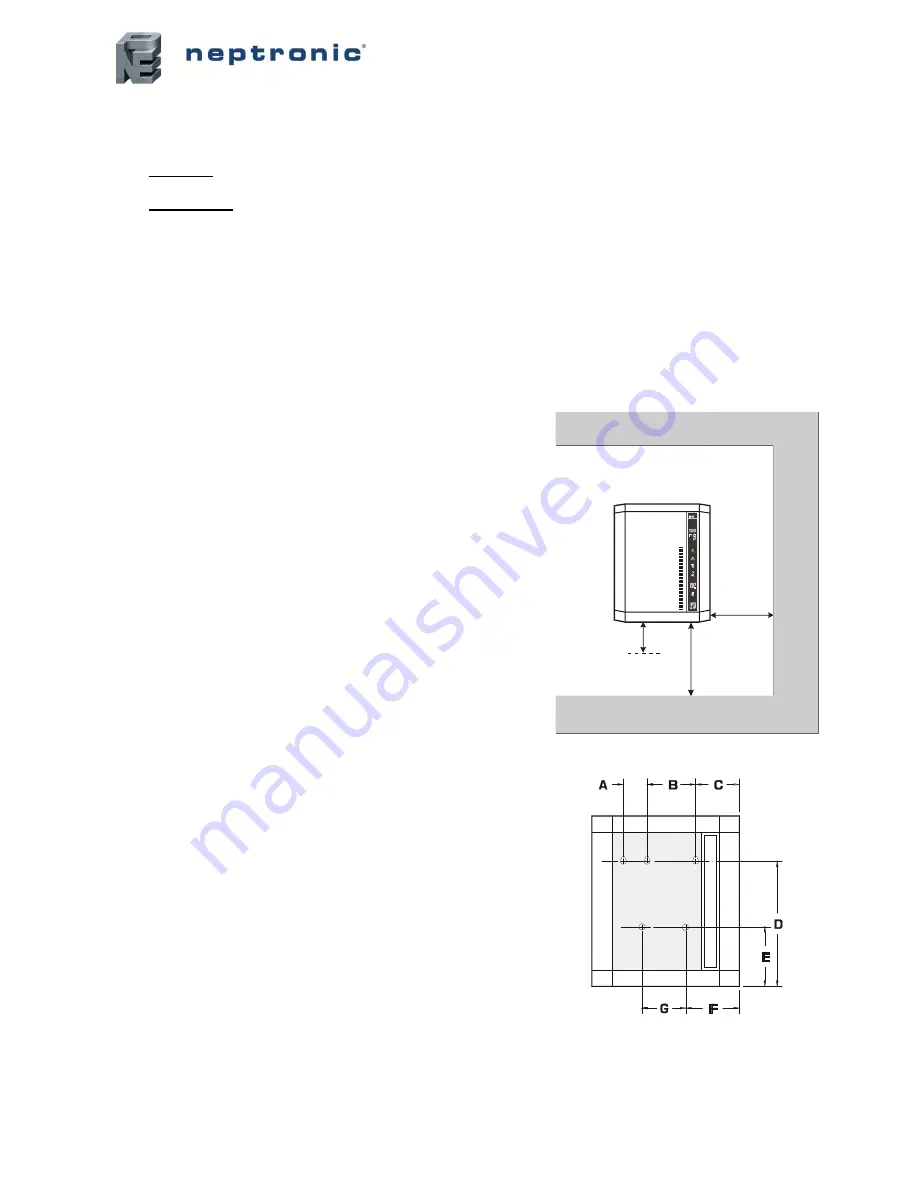

Positioning

The front panel and the right side (electrical compartment)

should be accessible in order to permit the servicing.

Leave a clearance of at least 1,25m to the front panel and

0,6m to the right side.

The humidifier should be mounted at a minimum of 1m to

1,2m above floor level.

Leave a clearance of at least 0,25m under the humidifier for

installation of water supply, drain piping and electrical

connections.

3.3.

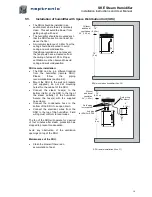

Wall mounting

Use the keyholes located on the back panel of the humidifier.

Before to proceed to the wall mounting, take off the

Evaporation chamber sub assembly (see section 12,

Servicing).

Check the solidity of the chosen support or wall (bricks,

concrete, stud partition wall, etc) on which the humidifier will

be mounted.

Drill holes for the upper anchors (holes with eyelet) into the

support or wall as per dimensions specified in the table

(illus.4).

The holes dimensions (diameter and depth) should by in

accordance with the recommendations of the chosen anchors.

Install then bolt anchors, if required.

Screw-on the 2 or 3 upper screws (holes with eyelet) of a

minimum diameter of #10 (6mm) (screws are not supplied).

Leave a clearance between head screws and wall in order to

permit the mounting of the humidifier.

Use the keyholes located on the back panel of the humidifier.

Hang on the humidifier to the 2 or 3 screws; it is preferable let

the front door open during this operation.

According to the size and weight of the humidifier, you may

need the help of a second person to assist you.

When the humidifier is positioned on the upper screws, tighten

the screws to secure the humidifier.

If applicable, install and secure lower screws.

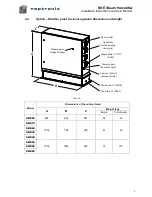

Positioning

(Illus. 3)

Front view

(Illus. 4)

(0,60 m)

(0,25 m)

(1 to 1,2 m)

10'’

24'’

39 to 48'’

E

n e p t r o n ic