SKE-XL Steam Humidifier

Installation Instructions and User Manual

7

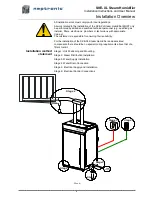

Handling & Unpacking

Lifting or handling MUST only be carried out by trained and qualified personnel. Ensure

that the lifting operation has been properly planned, risk assessed and that all

equipment has been checked by a skilled and competent Health & Safety

representative and effective control measures put in place.

It is the customer’s responsibility to ensure that operators are trained in handling heavy

goods and to enforce the relevant lifting regulations.

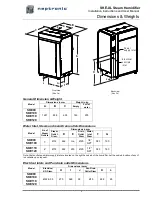

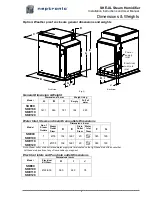

Refer to Dimensions & Weight section for system dry weights.

Handling and

Lifting

The SKE-XL Steam Humidifier MUST always be handled and lifted with care and

should remain in its original packaging for as long as possible prior to installation

The SKE-XL Steam Humidifier package may be carried using a forklift from the

underside. Caution should be exercised to ensure balanced load before lifting.

Lifting sling angle should be greater than 30

˚ to the horizontal.

Unpacking

SKE-XL Steam Humidifier is shipped on a wooden crate.

Remove packing wooden crate and skids prior to installation.

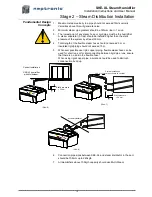

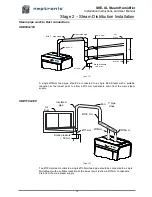

List of

accessories

supplied

Standard enclosure

2 sets of keys.

2 adjustable steam hose collars per steam outlet.

The present

Installation Instructions and User Manual

.

Wiring diagram

affixed onto the interior of the electrical compartment door.

!