SKE Humidifier

User Manual

23

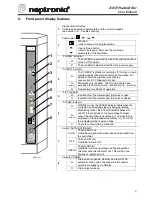

9.1.3. Diagnostic

mode

When the following conditions occur, the diagnostic messages override the scrolling information:

Display Description

Comment

N O

D E M A N D

No demand

Modulating humidifier: No analog signal to the

humidifier.

On/Off humidifier: Humidity level has exceeded the set

point of the humidistat or humidity level has exceeded

the set point on the high limit humidistat or airflow is not

detected by the air pressure switch.

SA FE T Y

O P E N

Safety open

Humidity level has exceeded the set point on the high

limit humidistat or airflow is not detected by the air

pressure switch (modulating humidifier only).

D R A I N

C Y C L E

Drain cycle

The humidifier is in the automatic drain mode.

C O N T A C T

D E L A Y

Contact delay

15 second delay for the power contactor to be

activated.

O V E R

H E A T E D

Overheated

The temperature inside the container has exceeded the

boiling temperature. The humidifier has automatically

shut off.

P R O B E

D E F E C T E D

Defected probe

The water level sensor is not operational. The

humidifier has automatically shut off.

N O

L E V E L

No water

Water has not reached the level probe

F O A M I N G

C Y C L E

Drain foam

AFEC (Anti Foam Energy Conservation) detects foam.

The humidifier drains for a few minutes and returns to

normal operation.

D R N / P R O B

B L O C K

Drain or probe block

The humidifier drains but the water level does not

decrease, the humidifier has automatically shut off.

Verify

RH Sens

Verify RH sensor

Signal from either HRM-X or HDM-X used as space

sensor is lower than 0.49 Vdc to terminal # 6 of

humidifier.

There might be a connection problem or a defective

sensor.

Verify

DCT Sens

Verify Duct sensor

Signal from HDM-X used as Hi limit duct sensor is

lower than 0.49 Vdc to terminal # 4 of humidifier.

There might be a connection problem or a defective

sensor.