SKE4-E Steam Humidifier

Installation Instructions and User Manual

Page | - 65 -

(

For models SKE4-E90 to E120, skip ahead to step 5.

)

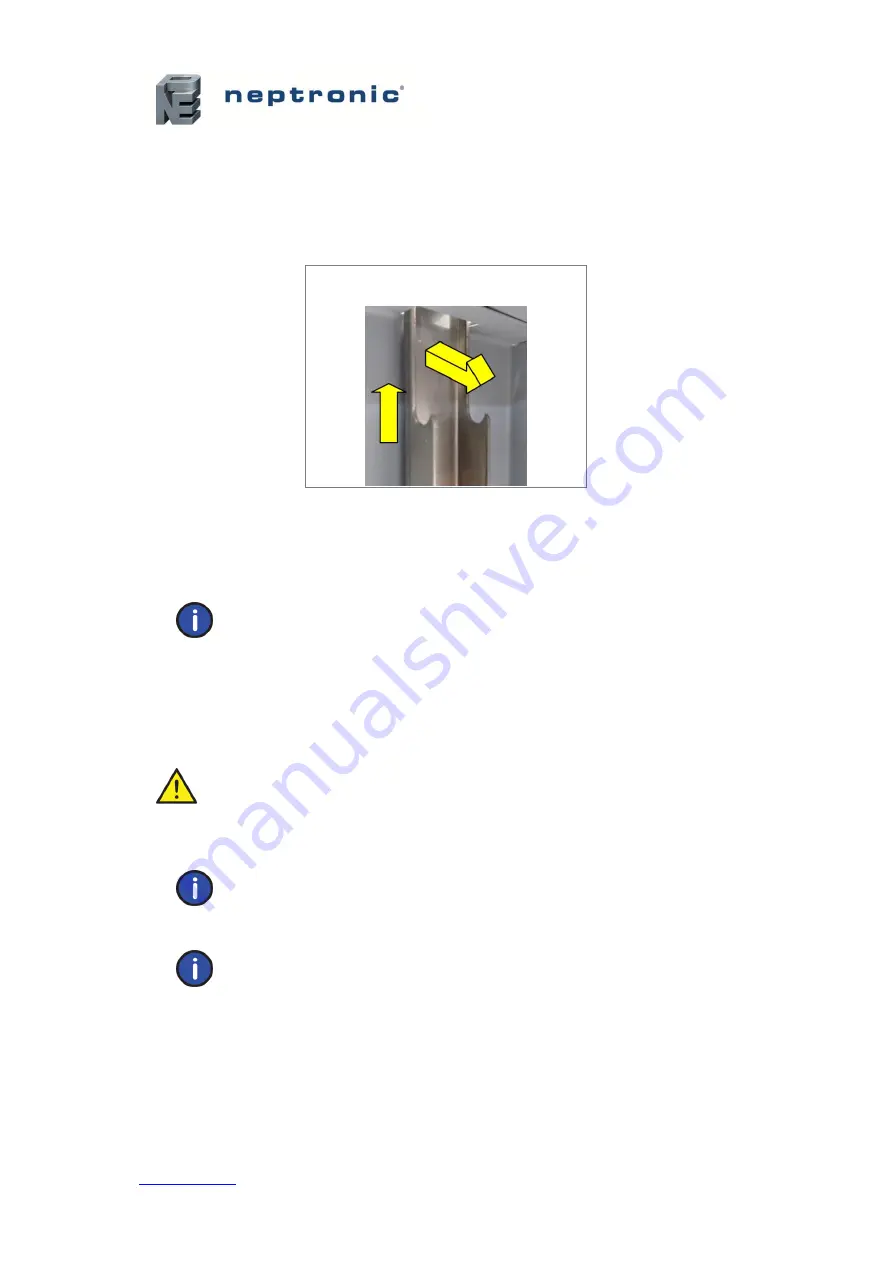

3. Once the clamps have been uncoupled, the tank will hang loose on the hooks located behind

the chamber. While the chamber is tilted, slightly lift the evaporation chamber upwards, by

raising it from the bottom with one hand, and holding onto the handle with the other.

4. Pull the evaporation chamber towards you using the handle, until it is fully removed from the

back hooks.

Complete motion performed to remove the

back of the chamber from the hooks.

5. Slide the evaporation chamber down using the rail-guided engagement system.

6. Let the evaporation chamber hang at the edge of the rail-guided system

(only for models

SKE4-E10 to E80)

or remove the chamber in order to begin cleaning.

The evaporation chamber will still contain a few inches of water. Ensure that your

footing is secure when removing the chamber. Take extra precautions when

removing the evaporation chamber from large humidifiers, which may feel heavy

when being pulled down.

7. Clean the evaporation chamber:

x

Remove the residue that has accumulated inside the chamber.

x

To clean out the remaining scale from the container, use a stiff brush (synthetic filament

only) and some vinegar or any weak acid suitable for cleaning stainless steel.

WARNING: The use of a wire brush or any non-recommended acid will void the

warranty.

x

Do not scrape off the walls of the chamber.

x

Ensure that the water inlet aperture is not blocked.

The heating elements are self-cleaning. Any mineral accumulation breaks off and

falls to the bottom during operation.

8. At the end of the maintenance procedure, replace the previous gasket attached to the top of

the evaporation chamber with a new one.

Contact your local Neptronic representative to order a new gasket. Refer to item 3 of

the Bill of Material section for the appropriate part number.