SKG3 Gas Fired Humidifier

Installation Instructions and User Manual

28

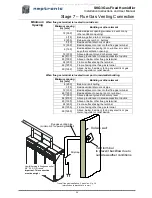

Stage 7 – Flue Gas Venting Connection

CAUTION

: For safe and efficient operation of the SKG3 Steam Humidifier, flue

gases (product of combustion) MUST be evacuated through a dedicated flue gas

venting system to the outside air.

CAUTION

: Flue gas venting must conform to local codes and regulations, and to

current ANSI Z223.1, ‘’National Fuel Gas Code’’ or CAN/CSA-B149.

The SKG3 Steam Humidifier MUST

be installed with a listed “BH vent’’ with a single

or double wall system for positive pressure and condensation. The vent must be

fabricated of AL29-4C stainless steel and be air and water tight.

Do not vent the SKG3 Steam Humidifier into another venting system serving another

appliance. The humidifier must be vented by its own approved/listed flue system.

Any flue gas venting pipe passing through floors, ceilings, and walls MUST be

installed with proper clearances to combustible material, and MUST be fire stopped

according to local codes and regulations.

Use only roof and wall penetration systems recommended by the flue gas venting

system manufacturer.

Install flue gas venting system in accordance with vent manufacturer’s instructions.

Flue gas venting pipe MUST be free of any restrictions or obstructions. The flue gas

venting pipe diameter MUST be the same as the SKG3 flue gas connector.

Do not use unlined masonry or concrete chimney as a flue gas venting system.

Flue gas venting system must not extend into, or pass through, any air duct.

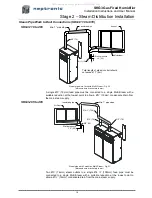

Installation of the flue gas venting pipe must be as direct as possible, minimizing the

number of turns or elbows, with a maximum of 6 elbows in total.

If flue gas venting pipe length exceeds 20 ft (6.1m), the exhaust vent pipe must be

insulated, in order to reduce the formation of condensate.

Approved ‘’BH

vent’’ systems

Cheminee Lining HEP, HEPL or HEPL2 rigid venting system,

Flexmaster Z-Vent Model SVE Series III rigid venting system,

DuraVent FasNSeal (single-wall) or FasNSeal W2 (double-wall) venting system,

MagnaFlex PV Model insulated flexible venting system,

Selkirk/HeatFab Saf-T Vent Model single-wall or double-wall venting system.

Flue Gas Venting

Specification

The Neptronic® SKG3 Steam Humidifier is a fan assisted condensing positive

pressure flue gas appliance.

Maximum flue gas temperature: Ambient 390

˚F (+ 217˚C).

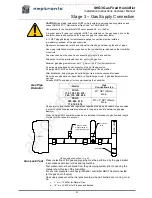

Maximum flue gas venting pipe length:

100ft (30m)

– 10ft (3m) x (total # of 90˚elbow) – 5ft (1.5m) x (total # of 45˚elbow).

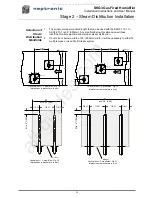

SKG3-110 to 210

Ø3’’O.D. (Ø 76mm)

SKG3-265 to 405

Ø4’’O.D. (Ø 100mm)

SKG3-505 to 810

Ø5’’O.D. (Ø 125mm)

Flue gas venting pipe diameter MUST be the same as the SKG3 flue gas connector.

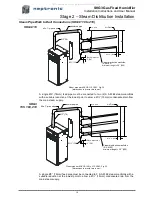

Minimum flue gas venting pipe upward gradient must be

¾’’ (20mm) in 40’’ (1m)

horizontal run or as per flue gas venting manufacturer’s instructions.

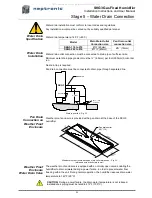

The Neptronic® SKG3 Steam Humidifier is a condensing appliance. As such, its high

efficiency may cause condensation in the flue gas venting.

Condensate drip tee must be installed, as

per flue gas venting manufacturer’s

instructions.

Flue Gas

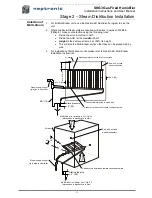

Terminal

Proper flue gas terminal

must be installed to prevent back flow or any other outside

weather condition that may affect proper operation of the SKG3 Humidifier.

Distances from the flue gas venting terminal to adjacent public walkways, buildings,

and any open able windows or building openings MUST conform to local codes and

regulations.

Flue gas terminal MUST be at a sufficient height above the ground level to prevent

blocking by accumulated debris.

Building materials MUST be protected from degradation by flue gases.

Vertical flue gas terminal MUST extend at least

40’’ (1m) above the roof top, and 24’’

(0.6m) above any ridge located within 10 feet (3m) from the terminal.

!

!

All manuals and user guides at all-guides.com