SKG4-E Gas Fired Humidifier

Installation Instructions and User Manual

Page | - 19 -

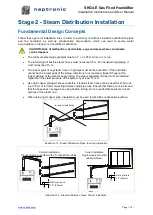

Stage 2 - Steam Distribution Installation

Fundamental Design Concepts

Follow these general installation rules in order to avoid any restrictions inside the distribution pipes

and the humidifier, as well as condensation accumulation, which can lead to severe water

accumulation in the duct or a humidifier malfunction.

The minimum steam pipe

gradient must be 7˚, i.e. 125 mm rise in 1 m run.

The total length of flexible steam hoses must not exceed 5 m. For insulated rigid piping, it

must not exceed 15 m.

The lowest point of any steam hose or rigid pipe must be the humidifier. If the humidifier

cannot be the lowest point of the piping, install one or more steam traps (S Type) at the

lowest point(s) of the steam supply piping. The steam separator (S trap) must be installed

higher than the static pressure of the system by at least 51 mm.

Use rigid copper piping whenever possible. Flexible steam hoses can be used for short runs

(up to 5 m) or for interconnecting between rigid pipe runs. Ensure that there are no kinks and

that the hose does not sag when using flexible tubing. Do not use flexible hoses for curved

portions of the steam line.

When using rigid copper pipe, insulation must be used to diminish condensation build up.

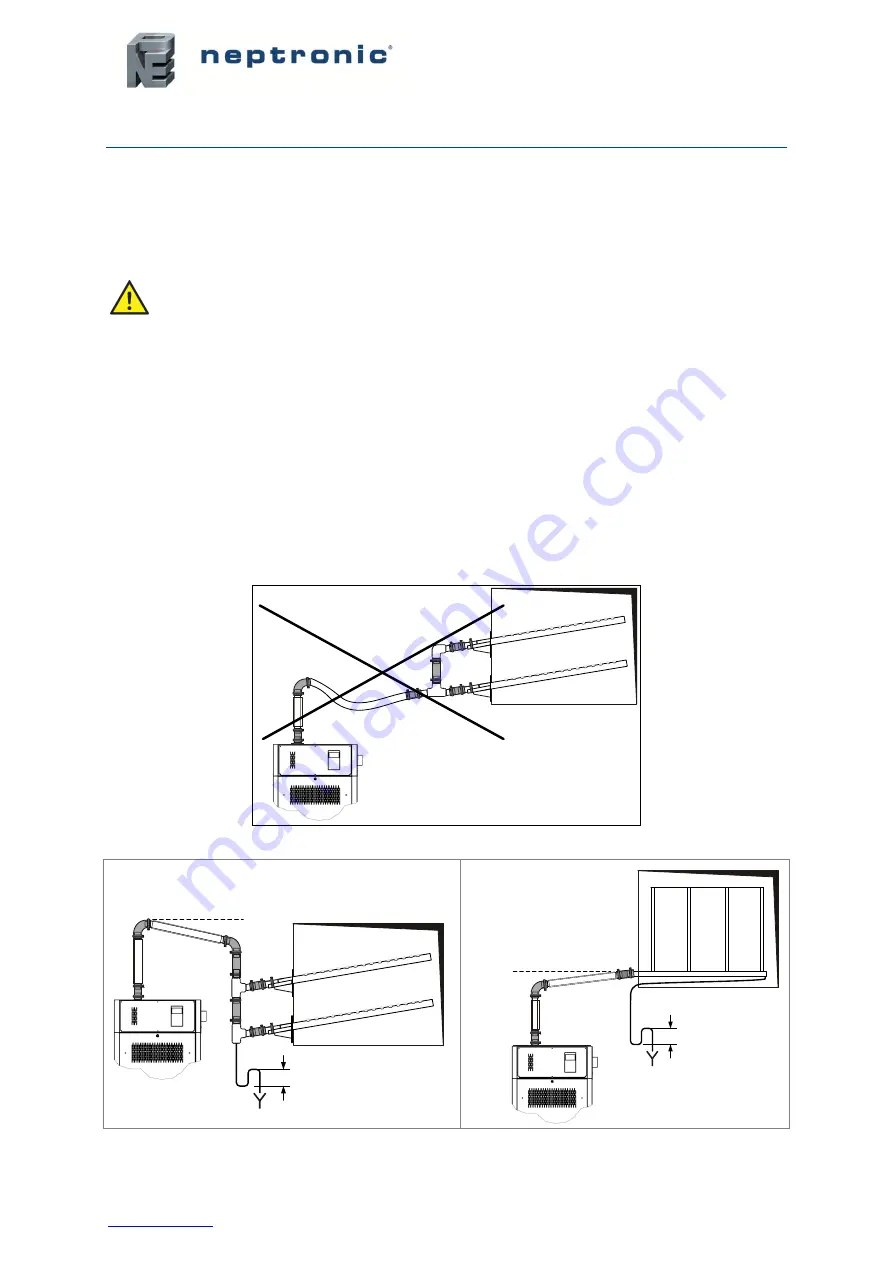

Incorrect Installation

Illustration 13 - Steam Distribution Pipes: Incorrect Installation

Min. 7°

Correct Installation

Single module humidifier with 2 S.A.M.E2 manifolds

Static pressure

+ 2" (50mm)

Min. 7°

Correct Installation

Single module humidifier

with Multi-Steam.

Static pressure

+ 2" (50mm)

Illustration 14 - Steam Distribution Pipes: Correct Installation

CAUTION: Risk of malfunction. Avoid kinks, sags and areas where condensate

can be trapped.

Summary of Contents for SKG4-E Series

Page 70: ...Notes ...

Page 71: ......