SKGE3 Gas Fired Humidifier

Installation Instructions and User Manual

14

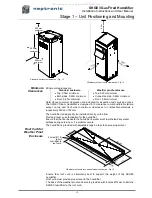

Stage 2 – Steam Distribution Installation

Fundamental

Design Concepts

1.

Maximum steam velocity in a pipe must not exceed 12m/s. Velocities above this

will generate noise.

2.

Minimum steam pipe gradient must be 7

˚ i.e. 125mm rise in 1000mm run.

3.

The lowest point of any steam hose or rigid pipe must be the humidifier.

Otherwise, a steam trap (S trap) must be installed at the lowest point of the

steam line. This steam trap must be installed higher than the static pressure of

the system by at least 50mm.

4.

Total length of the flexible steam hose must not exceed 5 m or insulated rigid

piping must not exceed 15 m.

5.

Whenever possible use rigid copper piping, flexible steam hose can be used for

short runs or for interconnecting between rigid pipe runs. Ensure that there is no

kink in the flexible hose.

When using rigid copper pipe, insulation must be used to diminish condensation

build up.

Min. 7°

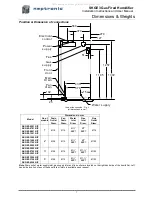

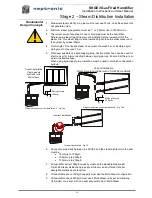

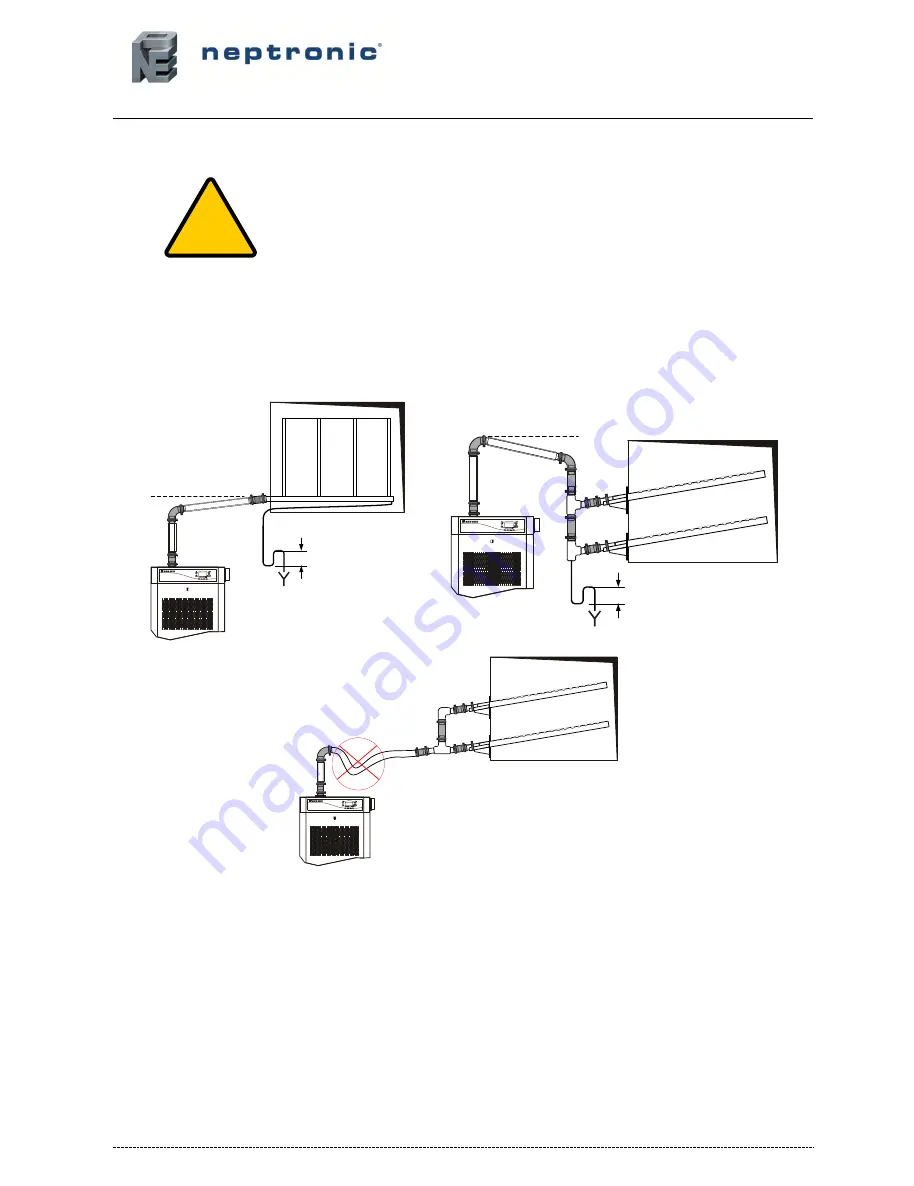

Correct Installation

Single module

humidifier with

Multisteam.

Static pressure

+ 50mm

Steam distribution correct installation 1 - Fig. 15a

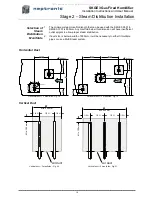

Min. 7°

Correct Installation

Single module humidifier with 2 S.A.M.E2 manifolds

Static pressure

+ 50mm

Steam distribution correct installation 2 - Fig. 15b

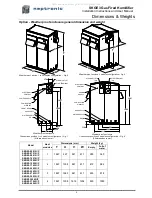

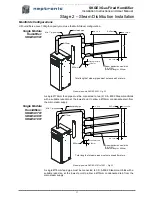

Incorrect installation - Fig. 16

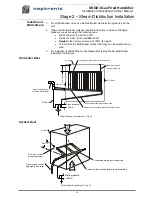

6.

Connection pipe sizes between the SKGE3 and the steam distributor in the duct

must be:

76mm up to 120kg/h

108mm up to 240kg/h

133mm up to 255kg/h

7.

All humidifier below 100kg/h capacity must use the standard Neptronic®

S.A.M.E2 Steam distribution pipes. Multi-Steam can be offered if shorter

absorption distances are required.

8.

All humidifiers above 100kg/h capacity must use the Multi-Steam configuration.

9.

All humidifiers above 240kg/h must use 2 Multi-Steam units per Air Handling

Unit (AHU) or air duct, with an equal duty split to each Multi-Steam

!

Incorrect Installation

All manuals and user guides at all-guides.com