SKR Humidifier – kit N

User Manual

www.neptronic.com

16

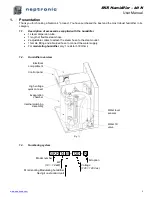

11. Start up procedure

Follow this start-up procedure to avoid improper system operation:

1. Ensure that steam distribution, electrical and plumbing connections have been done in accordance with the

instructions in this manual.

a) Remove the humidifier cover.

CAUTION: RISK OF ELECTRIC SHOCK, ENSURE THAT THE POWER IS TURNED OFF BEFORE

REMOVING THE COVER.

b) Ensure that the control wiring has been made in accordance with the instructions in this manual.

c) Ensure that dip switches (section 10, DS1) are correctly set.

d) Verify that the drain connections are connected to an open main drain of sufficient diameter.

e) Re-install the humidifier cover.

2. Open the water shut off valve (external to the humidifier).

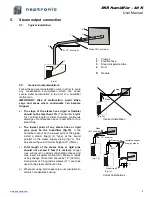

3. Turn on the power to the humidifier at the breaker/fused disconnect. The ''

POWER

'' indicator, located on the

control panel, will flash.

4. Press the ''

POWER

" push button located on the control panel. The ''

POWER

" indicator will stay on

continuously.

5. Perform a manual cleaning cycle:

a) The fill cycle is activated automatically when the evaporation chamber does not contain water.

b) When the ''

FILL

'' indicator is off, press the “

DRAIN

” push button.

c) The ''

DRAIN

'' indicator will come on and the water will drain from the evaporation chamber.

d) The evaporation chamber will fill with water and drain again.

e) When the ''

DRAIN

'' indicator turns off, press on the ''

POWER

" push button.

f) Repeat steps ''b'' through ''e'' one more time to ensure proper cleaning of the evaporation chamber.

6. Your humidifier is now fully operational. No other action is necessary; your

SKR

humidifier will produce

steam upon demand from control(s).

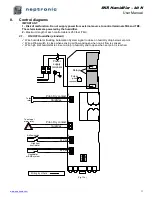

12. Description of operation of the SKR

Press the ''

POWER

'' push button (if the indicator is flashing) to start the humidifier (''

POWER

'' indicator will

light continuously). If the evaporation chamber does not contain water, the fill cycle is activated

automatically (''

FILL

'' indicator is on).

If there is no demand from the humidity controller, the humidifier is in a standby mode (''

STEAM

'' indicator is

off).

On a demand of humidity, the contact to activate the ventilation system fan closes (''

FAN

'' indicator is on)

and the relays close to power the electric element in the evaporation chamber (''

STEAM

'' indicator is on).

The water in the evaporation chamber will start to boil and evaporate. The steam is released through the

opening in the cover of the evaporation chamber. The steam will travel in the flexible steam hose and

disperse inside the supply duct through the steam dispersion tube.

During the evaporation sequence, a certain amount of water is evaporated. The water supply valve will

open to replenish the water in the evaporation chamber.

Depending on the selected drain period (section 10, DS1-1), the water in the evaporation chamber will be

drained (''

DRAIN

'' indicator is on) to renew the water and to evacuate the minerals inside the evaporation

chamber.

The

SKR

operates at full capacity until the programmed humidity level set point is reached. When the set

point is reached, the humidifier will revert to standby mode. The contact to activate the ventilation system

fan (section 10, TB-2) will remain closed for a period of four minutes after steam production has stopped.

When the humidity level is below the set point, the humidifier will produce steam again. If there is no

humidity demand for a period of more than 72 hours, the humidifier will drain the water from the evaporation

chambers automatically and go into standby mode