36

Technical Information

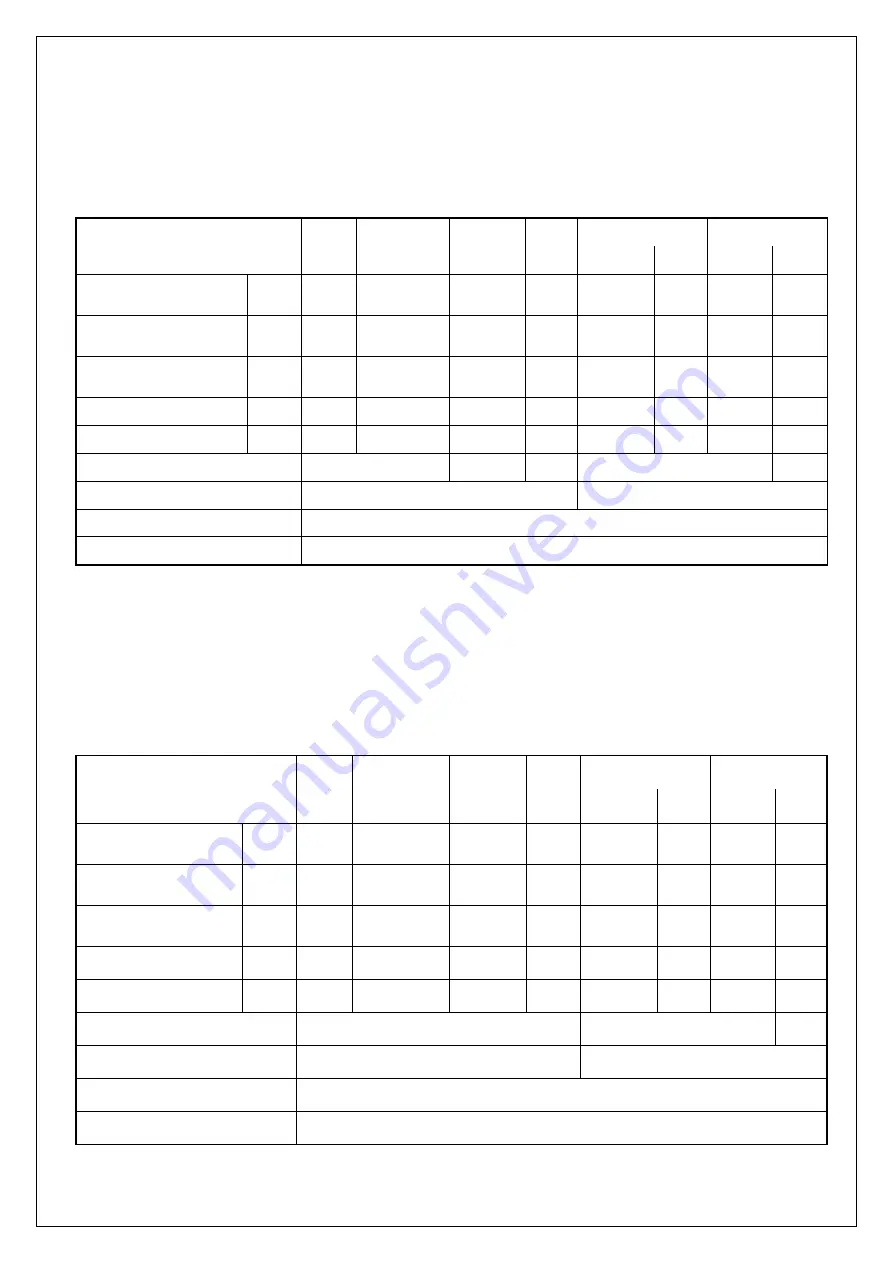

5.2 Technical Data

H15

Gas type

G20

G20/G25

G20/G25

G25

G30/G31

G31

I

2H

,I

2E

I

2E+

I

2ELL

I

2

I

3B/P(30/50)

I

3+

I

3P(37,50)

I

3P(30)

Supply Pressure

mbar

20

20/25

20

25

30/50

28-

30/37

37/50

30

Nominal Heat Input

Gross (Hs)

kW

6.9

6.9

6.9

6.9

6.9

6.9

6.9

6.9

Nominal Heat Input

Nett (Hi)

kW

6.2

6.2

6.2

6.2

6.4

6.4

6.4

6.4

Consumption

m³/hr 0.631 0.631/0.741

0.741

0.741

0.191

0.191

0.248

0.248

Burner Pressure (hot)

mbar

15

15\22

16

22

28.9

28.9

36

29

Injector Marking

480

560

480

160

180

Pilot

446.0330.24

446.0330.44

Efficiency Class

1

Nox Class

5

H25

Gas type

G20

G20/G25

G20/G25

G25

G30/G31

G31

I

2H

,I

2E

I

2E+

I

2ELL

I

2

I

3B/P(30/50)

I

3+

I

3P(37,50)

I

3P(30)

Supply Pressure

mbar

20

20/25

20

25

30/50

28-

30/37

37/50

30

Nominal Heat Input

Gross (Hs)

kW

9

9

9

9

7.8

7.8

7.8

7.8

Nominal Heat Input

Nett (Hi)

kW

8.1

8.1

8.1

8.1

7.2

7.2

7.2

7.2

Consumption

m³/hr 0.828 0.828/0.960

0.960

0.960

0.213

0.213

0.277

0.277

Burner Pressure (hot)

mbar

12.4

12.4\17.8

17.8

17.8

28.6

28.6

36

29

Injector Marking

650

180

220

Pilot

446.0330.24

446.0330.44

Efficiency Class

1

Nox Class

5

Summary of Contents for C15

Page 13: ...13 Installation instructions 3 5 Fuel Bed Arrangements H15 LPG ...

Page 14: ...14 Installation instructions H15 NG ...

Page 15: ...15 Installation instructions H25 LPG ...

Page 16: ...16 Installation instructions H25 NG ...

Page 17: ...17 Installation instructions H35 LPG ...

Page 18: ...18 Installation instructions H35 NG ...

Page 19: ...19 Installation instructions TQH35 LPG ...

Page 20: ...20 Installation instructions TQH35 NG ...

Page 21: ...21 Installation instructions H45 LPG ...

Page 22: ...22 Installation instructions H45 NG ...

Page 23: ...23 Installation instructions TQH15 LPG ...

Page 24: ...24 Installation instructions TQH15 NG ...

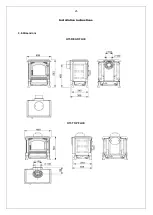

Page 25: ...25 Installation instructions 3 6 Dimensions H15 REAR FLUE H15 TOP FLUE ...

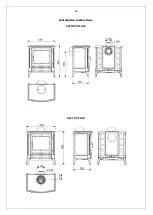

Page 26: ...26 Installation instructions S25 REAR FLUE S25 TOP FLUE ...

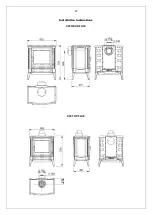

Page 27: ...27 Installation instructions S35 REAR FLUE S35 TOP FLUE ...

Page 28: ...28 Installation instructions RH35 REAR FLUE RH35 TOP FLUE ...

Page 29: ...29 Installation instructions H45 REAR FLUE H45 TOP FLUE ...

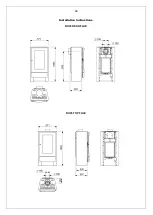

Page 30: ...30 Installation instructions TQH15 TOP FLUE ONLY ...

Page 31: ...31 Installation instructions TQH35 ...

Page 35: ...35 Technical Information Countries of destination types of gas ...