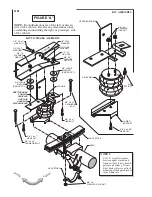

FIGURE "B"

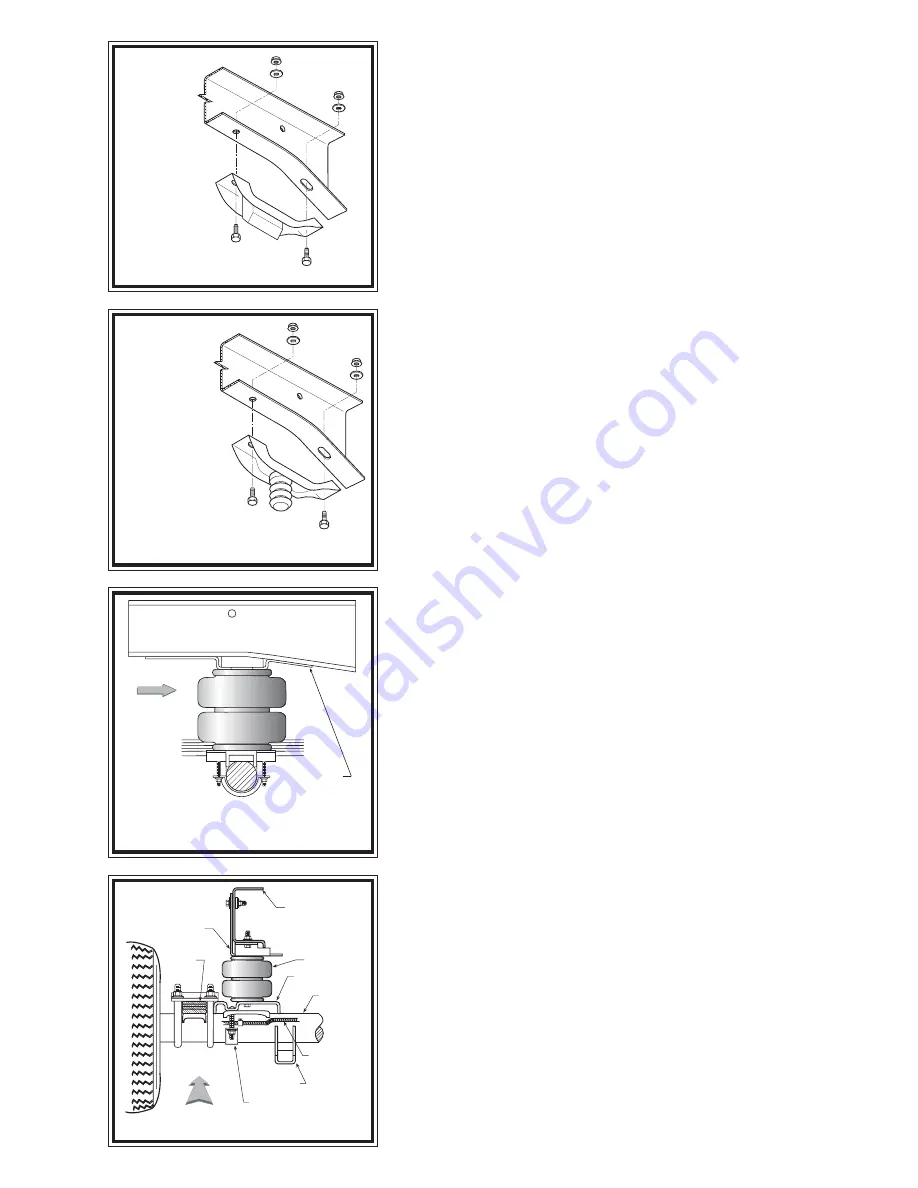

FIGURE "C"

S

TEP

1 - P

REPARE

THE

VEHICLE

Remove the positive battery cable. With the vehicle on a solid, level surface

chock the front wheels. Raise the vehicle by the axle and remove the rear wheels.

After the removal of the wheels lower the vehicle so the axle rests on jack stands

rated for your vehicles weight.

This installation assumes that there is no load in the truck.

N

OTE

:

This kit is designed to fit both two-wheel and four-wheel drive vehicles. The

jounce bumper and brackets must be removed for installation of this kit. The

jounce bumper and bracket on the two-wheel drive can be unbolted and removed

see Figure "B".

The jounce bumper and bracket on the four-wheel drive may be

bolted or riveted in place, depending on model year. Simply unbolt the jounce

bumper bracket and remove from the frame

see Figure "C"

. On older models,

remove the jounce bumper by drilling out two rivets that fasten the bracket to the

frame. Complete the removal by cutting off the heads with a cold chisel. The

completion of the kit installation is the same for the two-wheel and four-wheel

drive.

S

TEP

2 - P

RE

-

ASSEMBLE

THE

KIT

This kit is supplied with a right and left upper bracket. Begin by installing the

left (driver's side) upper bracket. This bracket will have the "over-bent tab"

see

Figure "D".

The lower bracket is the same for both sides. Align the studs on the

top of one of the air springs with the mounting holes in the upper bracket while

ensuring that the air hole is visible through the slot in the upper bracket. Insert

the studs into the holes and secure the air spring to the upper bracket with 3/8"

-16 flanged lock nuts

see Figure "A"

. Next, install the male push-to-connect air

fitting in the air inflation hole

.

Tighten the air fitting securely to engage the orange

thread sealant.

To attach the lower bracket to the air spring, first position the bracket on the

axle housing over the jounce pad

see Figures "A" & "E".

Position the bracket so

that the narrow end is toward the center of the vehicle. The air spring must be

secured to the lower bracket through the forward hole. Once the correct mounting

hole for the lower bracket has been identified, remove the bracket from the axle and

fasten to the air spring using a 3/8" -16 x 3/4" hex bolt

(finger tight). Note that

this bolt will be tightened in Step 3.

S

TEP

3 - I

NSTALL

THE

ASSEMBLY

TO

THE

VEHICLE

Set the assembly in place on the axle housing over the jounce pad. The lower

bracket should butt against the U-bolts on the leaf spring

see Figure "E"

. Position

the assembly so that the upper bracket is aligned vertically against the outside

surface of the frame rail.

On some vehicles there may be a rivet head on the bottom of the bottom surface

of the frame rail that will prevent the upper bracket from being mounted flush

against the frame. To assure that the upper bracket clears the rivet head, install

four large flat washers between the upper bracket and the bottom surface of the

frame rail

see Figure "A".

Installation of the flat washers is only necessary if your

vehicle has a rivet head on the bottom of the frame rail. Insert a 1/4" -20 x 1" bolt

through the vertical tab of the upper bracket and an existing hole in the frame rail.

Secure with washers and a nut

see Figure "A".

On some models, a hole must be

drilled in the frame rail for the bolt to pass through. Using the upper bracket as

a template, drill a 5/16" hole though the frame rail. Make sure that all electrical,

brake, and fuel lines are cleared from the path of the drill.

The tabs on the bracket will be secured to the lower frame flange using 3/8"

flanged lock nuts and 3/8"-16 x 1" hex bolts

see Figure "A".

Note: on the driver's

side of the vehicle the 1/4" bolt will also hold a clip (on some models) used to

hold brake and fuel lines. Secure the clip to the 1/4" bolt to secure the lines.

Align the lower bracket against the U-bolts over the leaf spring stack

see

Figure "E"

. After the bracket has been squared with the U-bolts, tighten the

3/8" hex bolt to secure the lower bracket to the air spring. Next, insert two

3/8" -16 x 3" carriage bolts into the square holes on the lower bracket. Install one

axle strap on the bottom of the axle housing

see Figure "A"

. Slide the axle strap

FIGURE "D"

FRONT

OVER-BENT

TAB

VIEW OF DRIVER’S SIDE ASSEMBLY

FROM INSIDE OF VEHICLE

DRIVER'S SIDE

FRONT

FRAME RAIL

AIR SPRING

LOWER BRACKET

UPPER BRACKET

BRAKE LINE

SHOCK

BRACKET

BRACKET STRAP

AXLE

LEAF

STACK

FIGURE "E"

TWO-WHEEL

DRIVE VEHICLES

SOME FOUR-WHEEL

DRIVE VEHICLES MAY

HAVE BOLTS, OTHERS

WILL HAVE RIVETS