6

untouched.

Skin that forms on the top of paint can clog the

sprayer. Remove skin before mixing. Strain with

a funnel with a filter attached or through hosiery

to remove any impurities that could clog system.

Before starting have gloves, paper towels, rags

etc. available for unexpected spills.

Filing the Canister

1. Unscrew the Canister. Stand the canister on a

smooth and horizontal surface.

2. Pour the properly thinned and strained

material to be sprayed into the canister.

3. Clean any residual liquid from the threads or

sides of the canister and sprayer.

4. Starting the threads evenly, screw the lid,

completely onto the top fill canister. Check

the lid to make sure it is threaded on

squarely and completely before picking up

the sprayer.

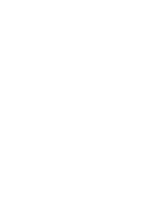

Adjust Spray Pattern

The spray pattern shape is adjusted by turning

the ears of the air cap to either the vertical,

horizontal, or diagonal position. The position of

the air cap and the corresponding spray pattern

shape are shown below.

Material Flow Adjustment

Set the material volume by turning the regulator

on the trigger of the spray gun.

Turn to “+” mark direction increase the flow of

liquid and turn to “-“ direction decrease the flow of

liquid.

For thicker materials, it is recommended that you

start with the highest material flow setting and

then gradually decrease the flow to suit your

particular spraying needs.

For thinner materials, it is recommended that you

start with a low material flow setting and then

gradually increase the flow to suit your particular

spraying needs.

Always test the spray pattern on scrap cardboard

or similar material first, Begin with flow control

knob on highest flow setting. If less flow is

desired, dial the flow control knob to decrease the

flow of liquid.

Heavier, thicker material should be sprayed with

the flow control knob on high flow setting.

Thinner material should be sprayed with the flow

control knob on low flow setting.

Proper Spraying Technique

If spraying with an HVLP spray system is new or

unfamiliar to you. It is advisable to practice on a

piece of scrap wood or cardboard before

beginning on your intended workpiece.

Surface Preparation

All objects to be sprayed should be thoroughly

cleaned before spraying material on them. Areas

not to be sprayed may, in certain cases, need to

be masked or covered.

Spray Area Preparation

The spray area must be clean and free of dust in

order to avoid blowing dust onto your freshly

sprayed surface.

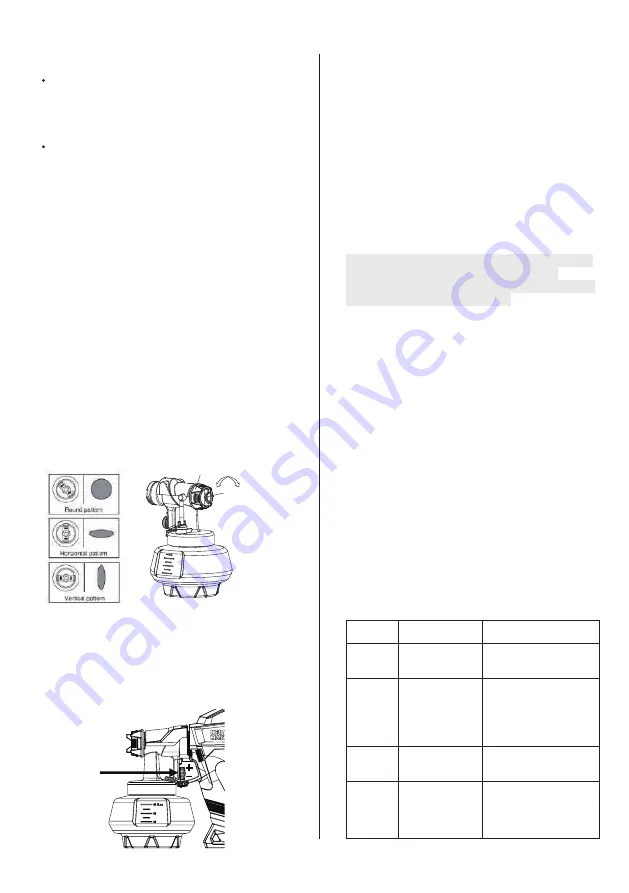

Nozzle size pickup

Select right size of nozzle base upon the material

you are going to use and the surface targeting

finishing. The small size of nozzle reflected to

finer coating. Dilute material if needed for better

quality of the coating

Nozzle

size

Recommended

material

Project Example

1.5mm

(White)

sealers, stains,

enamel,

varnish, dyes

Table, chair, bicycle,

shutter, cabinets,

wooden toy, model

2.0mm

(Red)

polyurethane,

chalk and milk

type paint

Railings, multi-frame

window frames,

heating pipes, boats,

yard furniture, garage

doors, metal garden

fences.

2.5mm

(Black)

low viscosity

primer, wall

paint

Internal wall, wooden

garden fence, wooden

pile, corridor

3.0mm

(Grey)

Latex plus

primers,

primer, wall

paint, latex, oil

enamels

External walls, outdoor

floors, deck

Nut

Air cup