MAINTENANCE

OM 0471MW-A

[32]

PROBLEM

CAUSE

CORRECTIVE MEASURE

8.

STREAKING

Thin strips of uncut grass are left behind the mower. Streaking is usually caused by operator error or poor

blade maintenance

•

Blades are not sharp.

•

Blades are worn down too far.

•

Engine speed is too slow.

•

Ground speed is too fast.

•

Deck is plugged with grass.

•

Not overlapping cutting rows enough.

•

Not overlapping enough when turning.

•

Sharpen your blades.

•

Replace your blades.

•

Always mow at rated PTO engine speed.

•

Slow down.

•

Clean out the mower.

•

Overlap your cutting rows.

•

When turning your effective cutting width

decreases - overlap more when turning.

9.

STINGERS

Stingers are sparse patches of uncut grass left behind the mower. Stingers are usually caused by operator error or

poor blade maintenance

•

Blades are not sharp or are nicked.

•

Blades are worn down too far.

•

Engine speed is too slow.

•

Ground speed is too fast.

•

Deck is plugged with grass.

•

Sharpen your blades.

•

Replace your blades.

•

Always mow at rated PTO engine speed.

•

Slow down.

•

Clean out the mower

10.

UNEVEN CUTTING

Uneven cutting is waviness or smooth troughs in the law surface. Uneven cutting is usually caused by mower

deck damage or mis-adjustment.

•

Deck is not leveled correctly.

•

Blades are dull or worn.

•

Blades are damaged.

•

Deck in clogged with grass clippings.

•

Deck shell is damaged.

•

Mower spindle is bent or loosed.

•

Blades are installed incorrectly.

•

Level the deck correctly.

•

Sharpen or replace the blades.

•

Replace the blades.

•

Clean out the deck.

•

Repair or replace the deck.

•

Repair or replace the spindle.

•

Reinstall the blades correctly.

11.

SCALPING

Scalping is when the mower deck comes close to or hits the ground. Scalping can be caused by the mower deck

misadjustment, unevenness in the lawn, or by mower deck bouncing because the ground speed is too fast

.

•

Lawn is uneven or bumpy.

•

Mower deck cutting height is set too low.

•

Ground speed is too fast.

•

Deck is not leveled correctly.

•

Tire pressure is low or uneven.

•

Roll or level the lawn.

•

Raise the cutting height.

•

Check and inflate the tires.

•

Correctly level the deck.

•

Check and inflate the tires.

12.

STEEPED CUTTING

Stepped cutting is sharp ridges or uneven levels left in the lawn surface. Stepped cutting is usually caused by

mower deck damage or misadjustment, or damage to mower blades.

•

Deck is not leveled correctly.

•

Tire are not properly inflated.

•

Blades are damaged.Blades are damaged.

•

Deck shell is damaged.

•

Mower spindle is bent or loosed.

•

Blades are installed incorrectly.

•

Level the deck correctly.

•

Check and inflate the tires.

•

Replace the blades.Replace the blades.

•

Repair or replace the deck.

•

Repair or replace the spindle.

•

Reinstall the blades correctly.

Summary of Contents for 266WMM

Page 9: ...GENERAL SAFETY INFORMATION OM 0471MW A 7 ...

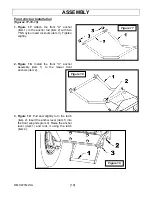

Page 10: ...GENERAL SAFETY INFORMATION OM 0471MW A 8 1 Safety stand 2 Secure point for safety stand ...

Page 12: ...SAFETY LABELS OM 0471MW A 10 Replace immediately if damaged ...

Page 37: ...PARTS OM 0471MW A 35 UPPER PART OF MOWER FRAME ...

Page 39: ...PARTS OM 0471MW A 37 FRONT HITCH COMPONENTS ...

Page 41: ...PARTS OM 0471MW A 39 REAR HITCH COMPONENTS ...

Page 43: ...PARTS OM 0471MW A 41 DRIVE SYSTEM ...

Page 50: ......

Page 51: ... ...