Operation

214811

21

5. OPERATION

5.1. Tractor/Loader Stability

5.1.1. Determination of Ballast

WARNING:

Reduce the risk of personal injury due to the

tractor tipping over or losing traction. Make sure

proper ballast is fitted.

The following information is based on recommendations

from ASAE EP562 March 2005. The information is

provided to reduce risk of machine overturning during

normal operation. Ballast tractor to meet requirements

outlined below.

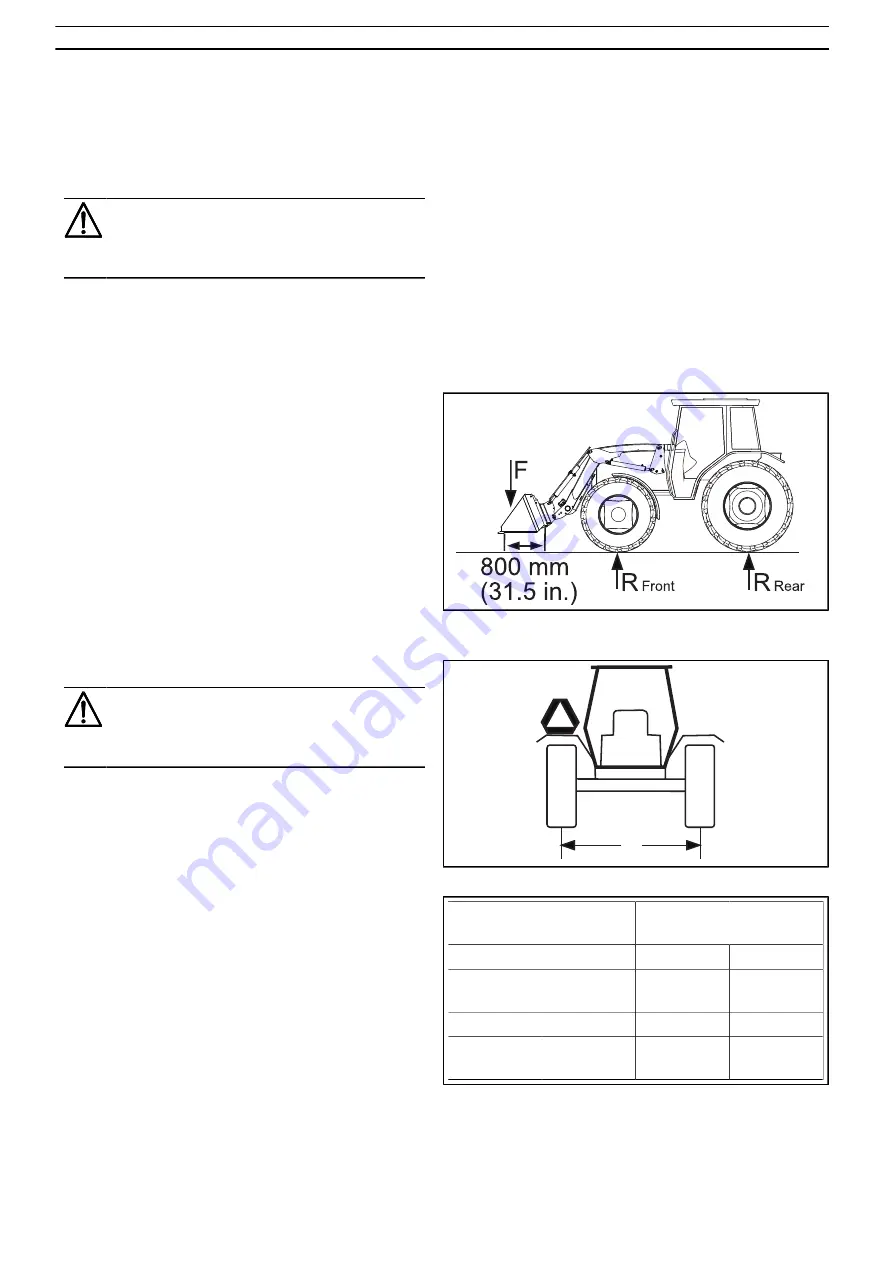

Place mass (weight) equivalent to loader lift capacity (F)

located 800 mm (31.5 in.) ahead of bucket pivot.

•

Raise loader until bucket pivot is level with loader arm

pivot (bucket in farthest forward position).

•

Apply rear wheel ballast and/or ballast box until

a minimum of 25% of total weight is on rear axle.

Tractor must be on level ground while measuring axle

load. Total weight includes ballasted tractor, loader,

bucket and payload (F).

•

When using loader for dedicated applications, operator

may determine appropriate ballast, based on maximum

load to be carried.

Fig. 44 Determination of Ballast

5.1.2. Minimum Tread Settings

CAUTION:

Overturning risk. The tractor can overturn if its

track is too narrow. Increase to maximum track

width for best stability.

Tread should be set as wide as practical considering the

environment of use.

Minimum tread settings recommended provide static

stability on a side slope of 15 degrees with loader

positioned just off the ground.

Unless otherwise specified by tractor manufacturer,

minimum rear tread settings should be selected from the

table.

Tractor/loader with high center gravity or unusual

configuration may require wider minimum tread setting to

achieve same level of stability.

A

Fig. 45 Minimum Tread Settings

TRACTOR MASS

(weight)

MINIMUM REAR TREAD

SETTING (A)

kg

pounds

mm

inches

Less than

2,250

Less than

4,960

1,575

62.0

2,250–3,650 4,950–8,030 1,675

65.9

More than

3,650

More than

8,030

1,825

71.8

Summary of Contents for 611TL

Page 2: ......