Operation

214811

22

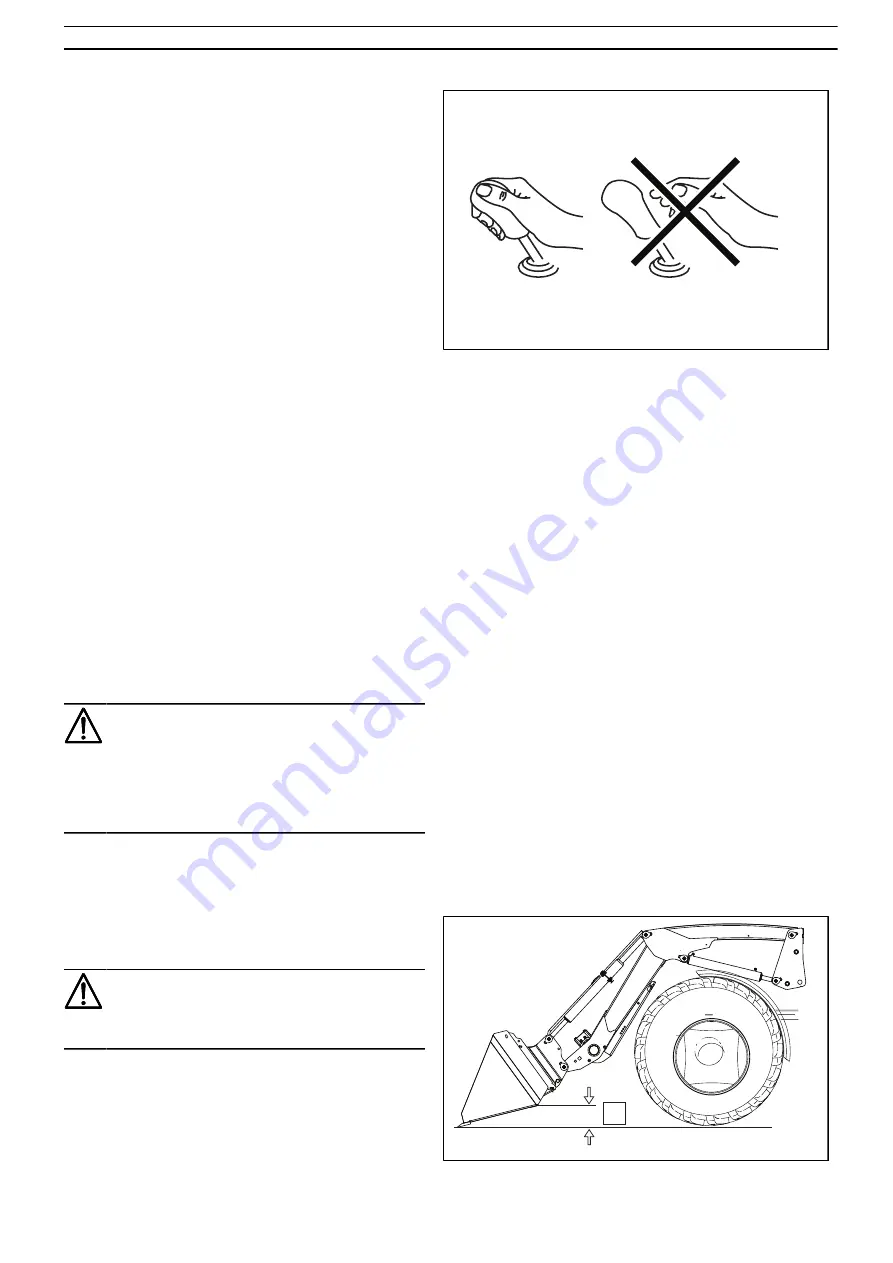

5.1.3. Joystick operation

The loader must not be combined with a programmable

joystick or other equipment that permits automatic or

unintended loader movement.

In order to prevent unintended loader motion, the loader

joystick controller must be designed to self neutralize.

When the operator releases his grip on the joystick, the

joystick must return to a non-operational neutral position

except for the float position in loader lower and bucket

dump circuits.

Fig. 46 The loader must not be combined with a programmable

joystick or other equipment that permits automatic loader

movement.

5.2. Connection and Operation

Options

The loader's hydraulic system can be connected to the

tractor hydraulic system in two ways.

Using alternative 1, the tractor hydraulic system is

connected to the loader control valve. This method is

available in the following variants:

Alternative 2 is to the tractors hydraulic remote valves

or a mid-mount loader valve furnished by the tractor

manufacturer to control the movements of the loader.

5.3. Disconnecting a loader

CAUTION:

Risk of crushing and pinching

The loader may fall downwards.

Always install a bucket or other suitable

implement on the loader before the loader is

disconnected from the tractor.

Park the tractor and the loader on a flat, firm surface.

Shut off the ride control load damper before disconnecting

the loader.

Tilt the bucket/implement forwards and lower the loader

so that the rear part of the bucket/implement is 4 - 6 inch

above the ground (A).

CAUTION:

If the rear section of the bucket/implement is

more that 6 inch above ground when uncoupling

the loader there is risk of damaging the hoses.

A

Fig. 47 Tilt the bucket/implement forward.

Summary of Contents for 611TL

Page 2: ......