2-109

87519804 NA

Issued 11-06

Bur

CHAPTER 2 - 667TA ENGINE OVERHAUL

ENGINE REPAIR MANUAL

VALVE CLEANING, CHECK AND GRINDING

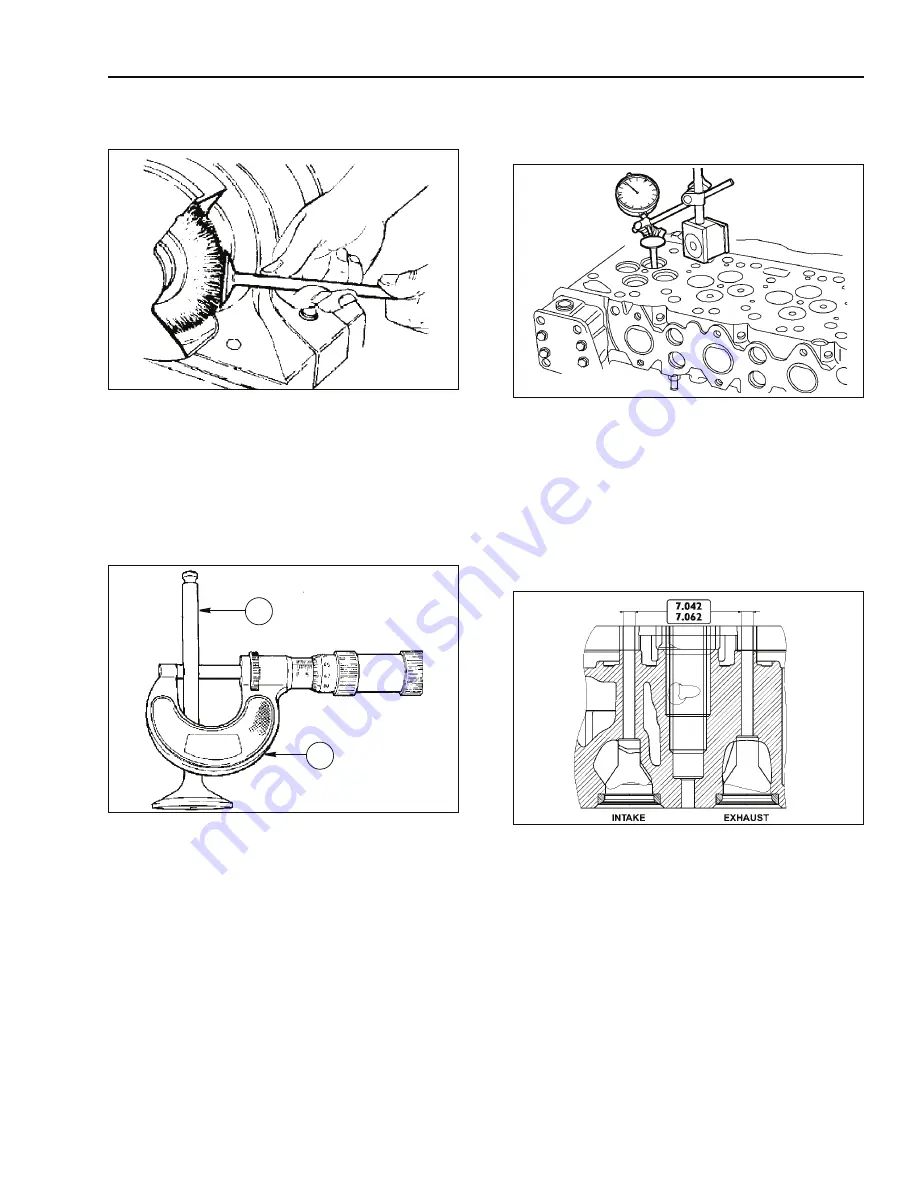

STEP 130

BS06K359

Figure 2-232

Remove the carbon deposits from the valves by

means of a special metal brush.

Verify that the valves do not show traces of seizing,

scoring or cracking.

Reface if necessary the valve seats by grinding,

removing as little material as possible.

STEP 131

BS06K360

Figure 2-233

Use a micrometer (2) to measure valve stem (1),

which must be equal to 6.97 to 6.99mm

(0.2744 to 0.2751 in.)

CHECKING ASSEMBLY PLAY, AND VALVE

CENTERING

STEP 132

BS06K361

Figure 2-234

Use a magnetic comparator (1) placed as shown.

Assembly play must be equal to 0.039 to 0.079 mm

(0.0015 to 0.0031 in.)

Turn valve (2) and check that the centering error is

not exceeding 0.03 mm (0.0011 in.)

VALVE GUIDE

STEP 133

BS06K362

Figure 2-235

Use a bore gauge to measure the valve guide inner

diameter, which must be equal to 7.042 to 7.062 mm

(0.2772 to 0.2780 in.)

2

1

Summary of Contents for 667TA/EBF

Page 4: ...SECTION 1 ENGINE REPAIR MANUAL II Issued 11 06 Bur 87519804 NA NOTES ...

Page 8: ...1 2 Issued 11 06 Bur 87519804 NA CHAPTER 1 DIAGNOSTICS ENGINE REPAIR MANUAL NOTES ...

Page 16: ...1 10 Issued 11 06 Bur 87519804 NA CHAPTER 1 DIAGNOSTICS ENGINE REPAIR MANUAL NOTES ...

Page 22: ...2 4 Issued 11 06 Bur 87519804 NA CHAPTER 2 667TA ENGINE OVERHAUL ENGINE REPAIR MANUAL NOTES ...

Page 144: ...3 2 Issued 11 06 Bur 87519804 NA CHAPTER 3 CHARGING AND START UP ENGINE REPAIR MANUAL NOTES ...

Page 150: ...3 8 Issued 11 06 Bur 87519804 NA CHAPTER 3 CHARGING AND START UP ENGINE REPAIR MANUAL NOTES ...