4

SECTION 01 - MAINTENANCE

Place some wedges under the wheels so as to pre-

vent the machine from moving.

Unauthorized modifications of the machine can

cause serious injuries. Do not carry out any modifi-

cation on this machine without obtaining prior

authorization from your Dealer. Any modification

carried out must be in conformity with the machine’s

technical specifications and must conform to current

safety regulations.

Do not carry out any welding operation on the

machine without prior authorization from your

Dealer.

Some of the machine’s components are subject to

type approvals. It is mandatory when replacing

those components to ensure that they are in con-

formity with regulations.

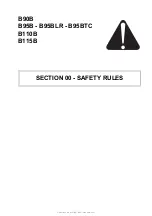

Hydraulic fluid or grease under pressure which pen-

etrates the skin can cause serious injury. Take the

necessary safety precautions (protective clothing

and face and hand protection) to prevent all such

risks. In addition, before handling these products,

read the manufacturer’s specific instructions for

their use. If hydraulic fluid penetrates the skin a doc-

tor must be called immediately.

When carrying out a welding operation on the

machine, as authorized by the manufacturer and in

accordance with his specifications, disconnect the

electric system by means of the battery master

switch, connect the welding set earth lead to the

component on which the welding is to be carried out

(never connect the ground lead to a hydraulic sys-

tem component) and disconnect the electric cables

of the motor control unit (in case of electronic

motors).

A burst tyre can cause serious injury.

Regularly check the condition of tyres and always

observe the inflation pressures defined in accord-

ance with the type of tyre and ground conditions.

When checking the tyre pressure or during an infla-

tion operation, never stay in front of the tyre but

always keep to the tread side.

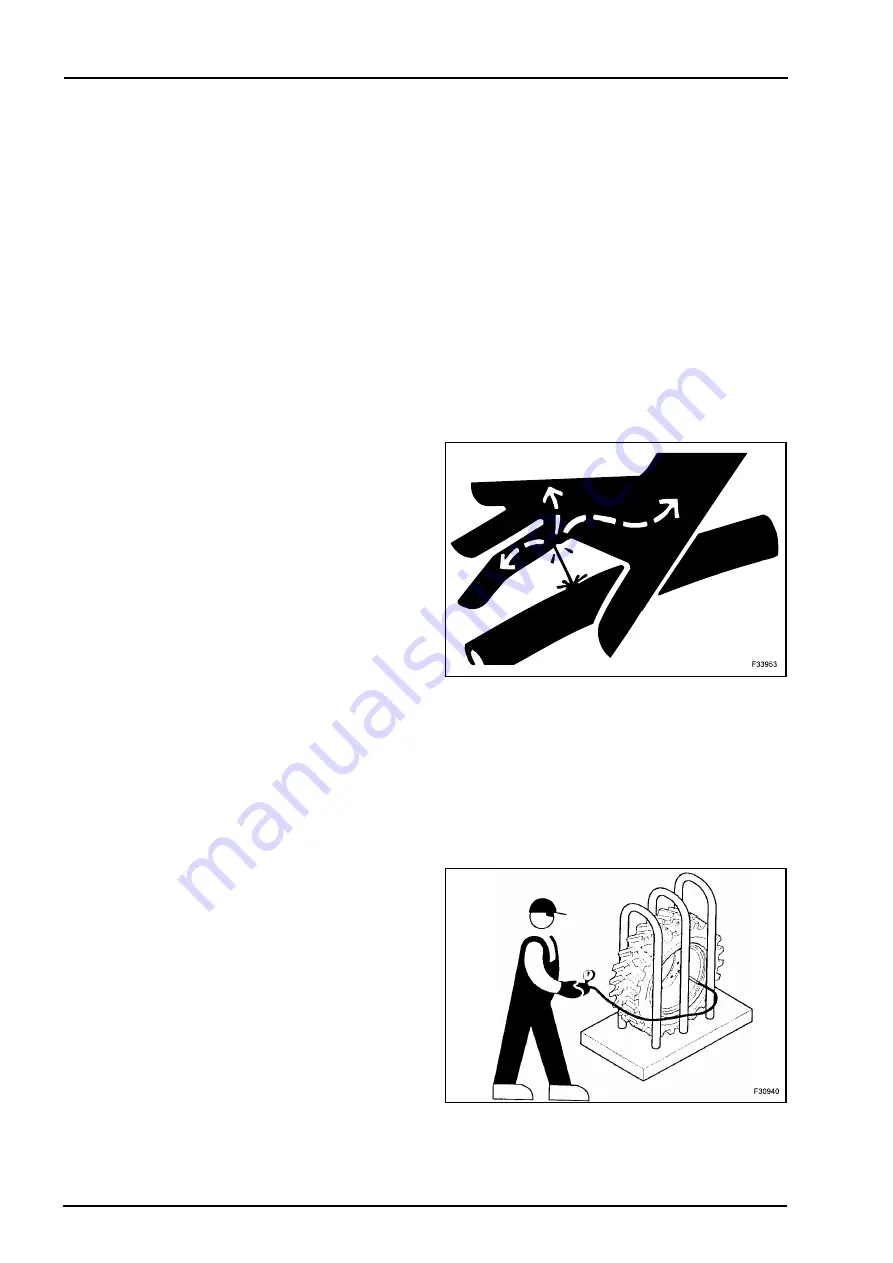

Always use an inflation cage when the wheel is

removed from the machine.

Keep all other persons away from the area.

Never weld near a tyre. It is essential to remove the

tyre before any welding operation.

Take the necessary safety measures to protect your

face when using compressed air.

The machine’s structure is in conformity with the

FOPS and ROPS protection standards.

Any modification (drilling, welding, etc.) may cause

that conformity to be invalidated.

Summary of Contents for B110B

Page 3: ...2 SECTION 00 SAFETY RULES Find manuals at https best manuals com...

Page 12: ...B90B B95B B95BLR B95BTC B110B B115B SECTION 01 MAINTENANCE...

Page 13: ...2 SECTION 01 MAINTENANCE...

Page 19: ...8 SECTION 01 MAINTENANCE NOTES...

Page 21: ...2 SECTION 02 TECHNICAL SPECIFICATIONS 1...

Page 51: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com...