INTRODUCTION

PIPE THREAD FITTING TORQUE

Before installing and tightening pipe fittings, clean the

threads with a clean solvent or Loctite cleaner and apply

sealant

L

OCTITE

® 567 PST P

IPE

S

EALANT

for all fittings

including stainless steel or

L

OCTITE

® 565 PST

for most

metal fittings. For high filtration/zero contamination sys-

tems use

L

OCTITE

® 545

.

PIPE THREAD FITTING

Thread Size

Torque (Maximum)

1/8-27

13 N·m

(

10 lb ft

)

1/4-18

16 N·m

(

12 lb ft

)

3/8-18

22 N·m

(

16 lb ft

)

1/2-14

41 N·m

(

30 lb ft

)

3/4-14

54 N·m

(

40 lb ft

)

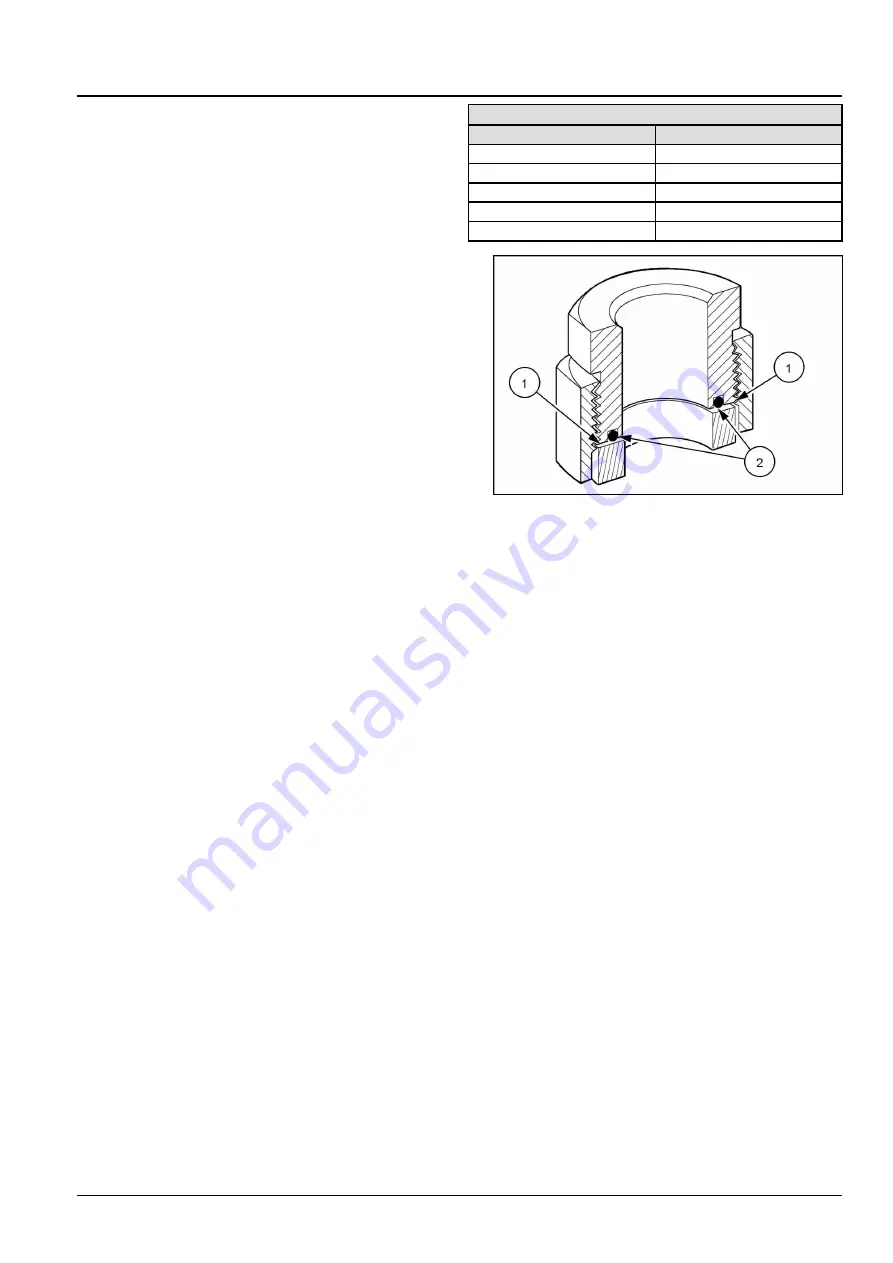

INSTALLATION OF ORFS (O-RING FLAT

FACED) FITTINGS

When installing ORFS fittings thoroughly clean both flat

surfaces of the fittings

(1)

and lubricate the O-ring

(2)

with

light oil. Make sure both surfaces are aligned properly.

Torque the fitting to specified torque listed throughout the

repair manual.

NOTICE:

If the fitting surfaces are not properly cleaned,

the O-ring will not seal properly. If the fitting surfaces are

not properly aligned, the fittings may be damaged and will

not seal properly.

NOTICE:

Always use genuine factory replacement oils

and filters to ensure proper lubrication and filtration of en-

gine and hydraulic system oils.

The use of proper oils, grease, and keeping the hydraulic

system clean will extend machine and component life.

50011183

2

48143704 20/04/2017

23

Summary of Contents for B80B

Page 2: ...SERVICE MANUAL B80B 48143704 20 04 2017 EN Find manuals at https best manuals com...

Page 6: ...INTRODUCTION 48143704 20 04 2017 1 Find manuals at https best manuals com...

Page 32: ...SERVICE MANUAL Engine B80B 48143704 20 04 2017 10...

Page 34: ...Engine 10 Engine and crankcase 001 B80B 48143704 20 04 2017 10 1 10 001 1...

Page 45: ...48143704 20 04 2017 10 1 10 001 12...

Page 46: ...Engine 10 Intake and exhaust manifolds and muffler 254 B80B 48143704 20 04 2017 10 2 10 254 1...

Page 51: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com...