E265C-E305C

SAFETY PRECAUTIONS

S2 - 16

SAFE MAINTENANCE

Prior to service in the machine:

- Park the machine on the level ground.

- Lower the bucket to the ground.

- Move the safety lever to the

LOCK

position.

- Switch off the Auto-Idle.

- Let the engine idle with no load for at least five

minutes until it has cooled down.

- Turn the ignition key to the

OFF

position to stop

the engine.

- Remove the ignition key from the start switch.

- Apply the "Maintenance in progress" tag (see

SAFETY DECALS in this Chapter). This tag can

be applied o the left-hand control lever, safety

lever or cab door.

To avoid accidents:

- Understand maintenance procedure before

starting the work.

- Keep the working area clean and dry.

- Do not spray water or steam inside the cab.

- Do not lubricate or service the machine when it

is in motion.

- Keep hands, feet and clothes far from moving

parts.

- Do not leave the machine unattended if

servicing requires the engine running.

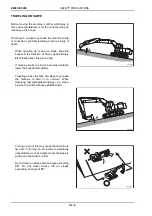

- If the machine is to be raised, place boom and

arm at an angle 90 to 110°. Lock machine

components which should be raised for

maintenance or repair using suitable supporting

means.

- Never work under a machine kept raised by the

boom.

- Inspect certain component regularly, repair or

replace as necessary. Refer to the Chapter

MAINTENANCE

in Operator's Manual.

- Keep all components in good condition and

properly install. Immediately repair any fault.

- Immediately repair any damage.Replace worn

or failed components. Remove grease, oil,

debris build-ups.

- Disconnect the negative cable from the battery

before carry out any work on he electrical sysem

or arc-welding on he machine.