INTRODUCTION

Basic instructions - How to use maintenance standards and

precautions

Application

1. When the machine is new:

Confirm that the performances are in accordance with standard specifications as compared to the performance

standards.

2. At specific self inspection: (Rule by country)

Use the data for the criterion, for the purpose of correction, adjustment and replacement.

3. When performances are deteriorated:

Determine whether it is caused by a fault or end of service life after long hours of operation, to be used for safety

and economical considerations.

4. When main components are replaced:

For example, use data to restore performances of pumps and others.

Terminology

Standard values

1. Values to be used to condition or assemble a new machine. Where special notes are not given, these values

represent standard specifications (machine with standard attachments and standard shoes).

Reference values for remedy

2. Values at which readjustment is required. In order to ensure performance and safety it is strictly prohibited to use

the machine over the specified values.

Service limit

3. This is the limit value at which reconditioning is impossible without replacement of parts. If the value is expected to

exceed the service limit before next inspection and correction are performed, replace the parts immediately. The

operation over the specified values causes increase of damage and requires the down time of machine, and also

causes safety problems.

Cautions to be exercised at judgment

Evaluation of measured data

Disagreement of measuring conditions, variations of data peculiar to a new machine, and measuring errors are to

be evaluated. Determine generally at what levels measured values are located, instead of determining whether or

not values fall within or run out of the reference values.

Determining correction, adjustment or replacement

Machine performances deteriorate with time as parts wear and some deteriorated performances may be restored

to new levels. Therefore, determine correction, adjustment or replacement, depending upon the operating hours,

kind of work and circumstances in which the machine is placed, and condition the machine performances to its

most desirable levels.

Other cautions to be exercised

Parts liable to degrade

1. Rubber products, such as, hydraulic hoses,

O-rings, and oil seals deteriorate with time: replace them at regular intervals or at overhauls.

47488366A 13/03/2013

25

Summary of Contents for E75CSR

Page 2: ...SERVICE MANUAL E75CSR 47488366A 13 03 2013 EN Find manuals at https best manuals com ...

Page 6: ...INTRODUCTION 47488366A 13 03 2013 1 Find manuals at https best manuals com ...

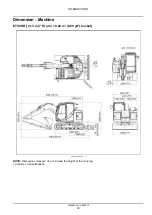

Page 29: ...INTRODUCTION Dimension SMIL13CEX1680FA 2 47488366A 13 03 2013 24 ...

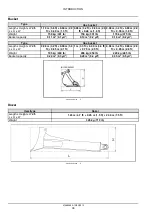

Page 48: ...INTRODUCTION Front attachment SMIL13CEX1701FA 2 47488366A 13 03 2013 43 ...

Page 49: ...INTRODUCTION 47488366A 13 03 2013 44 ...

Page 50: ...SERVICE MANUAL Engine E75CSR 47488366A 13 03 2013 10 ...

Page 51: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com ...