15

Operator's Manual

17

operating instructions

Hot water operation:

1. Follow the steps outlined for "START-UP/COLD WATER OPERATION".

2. Move the Burner Switch to the ON position. On initial start-up, water will begin

turning hot in approximately 20 seconds and will reach maximum temperature in

approximately 2-1/2 minutes, provided the trigger remains squeezed. The burner

will stop firing when the trigger is released.

NOTE: While spraying, it is normal for the burner to fire intermittently. The high-limit

switch will cause combustion to cease when the temperature of the discharged

water exceeds the maximum temperature setting of the switch. Combustion

will begin again when the temperature drops below the minimum setting.

At this point, the unit is operating as a hot water pressure washer. Be certain to be

extremely cautious when adjusting the pressure and controlling the trigger gun/lance

assembly to avoid the possibility of burns.

cleaning witH detergents:

NOTE: This feature is designed for use with mild detergents only. Since the cleaning

solution travels through various parts of the pressure washer, do not use corrosives

as they will cause extensive damage as well as pose a considerable safety hazard.

1. Refer to “Risk of Bodily Injury / Detergents”. Be certain to wear protective safety

attire as stated in warnings.

2. Prepare detergent solution according to label directions. (Never pump acids, alkalines,

abrasive fluids or solvents through the unit. Due to the unknown and often corrosive

characteristics of many detergents commonly used in the pressure washer cleaning

industry, it is recommended to use only mild detergents with this unit.)

3. Fully immerse the strainer end of the clear vinyl detergent hose into the

detergent solution.

4. DIRECT FEED: Be certain the adjustable grip on the dual lance is turned completely

clockwise for low pressure detergent operation.

NOTE: This injection system is designed to apply detergents under low pressure

only. It will not allow detergent solutions to be introduced into the system unless

the dual lance is set in the low pressure mode.

5. To apply solution; unlock the trigger gun and squeeze the trigger. In a few moments

a detergent/water mixture will exit the nozzle. Start spraying the lower portion of

the surface being cleaned and move up, using long overlapping strokes. Applying

from the bottom up helps avoid streaking. Allow to soak briefly. Avoid working on

hot surfaces or in direct sunlight to minimize the chances of the detergent drying,

which may result in damaging surfaces. Be certain to apply cleaning solution to

a small section at a time.

6. To rinse; lock the trigger gun in the “OFF” position,

DIRECT FEED: Rotate the adjustable grip on the dual lance counterclockwise

for high pressure.

7. Siphon a gallon of water through the detergent injection system after each use.

This prevents the possibility of corrosion or detergent residue causing mechanical

problems during the next use.

sHut-down:

1. Move the Burner Switch to the OFF position.

2. Squeeze the trigger and discharge the water for a period of three minutes to cool

the heat exchanger and high pressure hose. (Insufficient cool down period of

the high pressure hose will cause excessive wear and eventual rupturing of the

hose.)

3.

do not close the choke to stop the engine.

Backfire or engine damage may

occur. Turn the engine "OFF" as directed in the engine manual.

4. Close the engine fuel shut-off valve.

5. Turn the water supply "OFF".

6. Pointing the gun in a safe direction, trigger the gun momentarily to relieve trapped

pressure.

7. Disconnect and drain the nozzle assembly, gun, wand and hoses.

8. Store complete assembly in a non-freezing environment.

WARNING

risK of burn!

tHe water temperature

could become Very Hot

during Hot water oper-

ation. be cautious wHen

adJusting pressure or

controlling tHe trigger

gun/lance assembly.

detergent metering ValVe

Summary of Contents for MN2765HAHW

Page 1: ...operation manual MN2765HAHW MODEL NUMBER...

Page 8: ...8 8 Operator s Manual features 2500 psi HSP 2500 FEATURES 122208 CH...

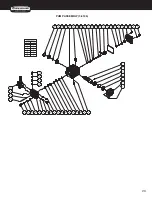

Page 24: ...24 4 Copyright 2011 EX 9836 101011 FLOW CHART EMF SYSTEM HSP115 080499 BAR HSP046 072996 BAR...

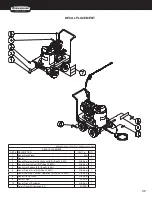

Page 29: ...29 12 yright 2011 EX 9836 101011 PUMP ASSEMBLY 3 0146...

Page 31: ...31 14 EX 983 UNLOADER ASSEMBLY 8 0515...

Page 40: ...40 26 yright 2011 EX 9836 1010 WIRING SCHEMATIC WIRING DIAGRAM...