SECTION 4 -- LUBRICATION AND MAINTENANCE

4--4

FUEL REQUIREMENTS

The quality of fuel used is an important factor for

dependable performance and satisfactory engine

life. Fuels must be clean, well-refined, and

non-corrosive to fuel system parts. Be sure to use

fuel of a known quality from a reputable supplier.

Use Number 2-D in temperatures above --7

°

C (20

°

F).

Use Number 1-D in temperatures below --7

°

C (20

°

F).

To obtain optimum combustion and minimum engine

wear, the fuel selected for use should conform to the

application and property requirements outlined in the

following chart.

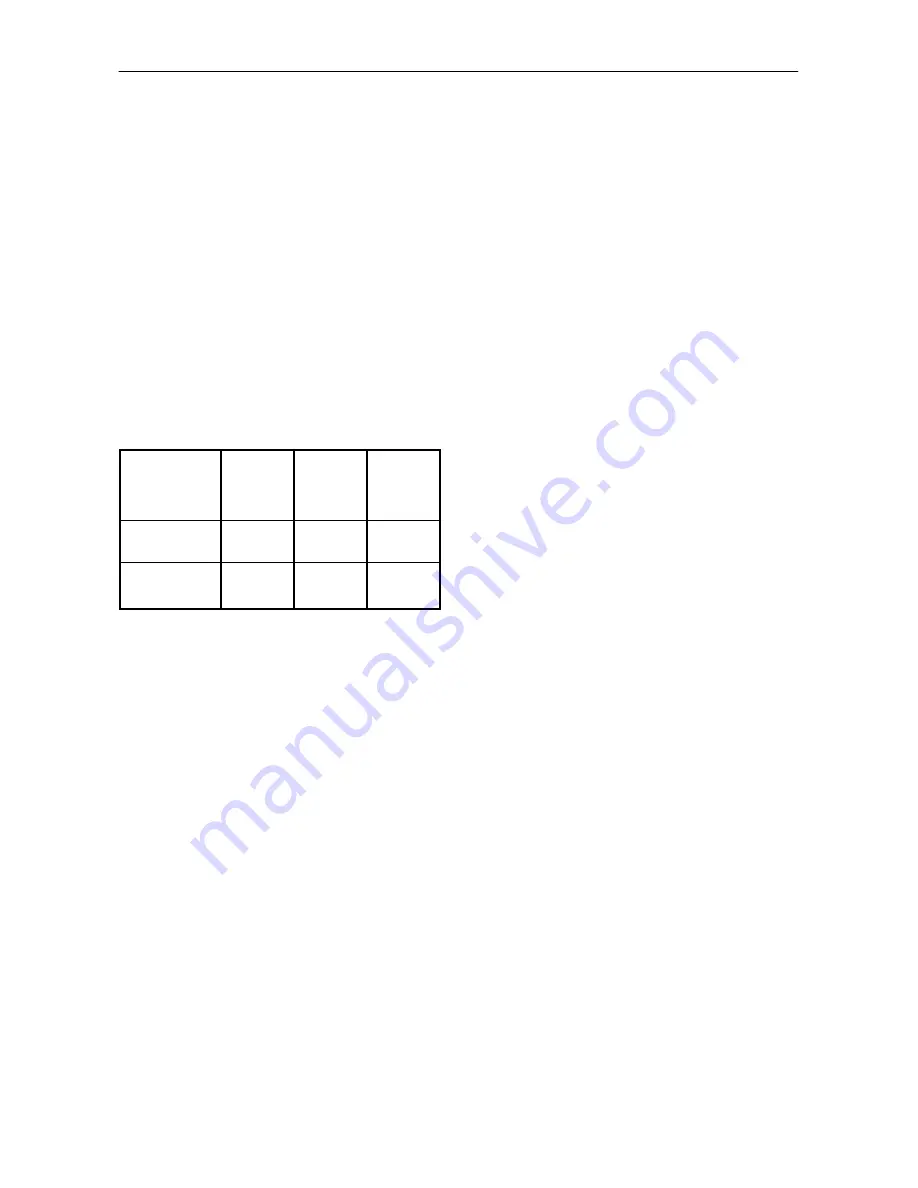

DIESEL FUEL SELECTION CHART

General Fuel

Classification

Final

Boiling

Point(Max)

Cetane

Rating

(Min)

Sulphur

Content

(Max)

No. 1--D

288

° ⊂

(550

°

F)

40*

0.3%

No. 2--D

357

°

C

(675

°

F)

40

0.5%

NOTE:

When long periods of idling or cold weather

conditions below 0

°

C (32

°

F) are encountered or

when continuously operating at an altitude above

5,000 ft

.

(1500 m) use Number 1-D fuel.

*

When continually operating at low temperatures or

high altitude, a minimum cetane rating of 45 is

required.

Using diesel fuel with sulphur content above 0.5%

requires more frequent oil and filter changes as

noted in the maintenance schedule.

The use of diesel fuel with a sulphur content above

1.3% is not recommended.

For the best fuel economy, use Number 2--D fuel

whenever temperatures allow.

Do not use Number 2-D fuel at temperatures below

--7

°

C (20

°

F). The cold temperatures will cause the

fuel to thicken, which may prevent the engine from

running. (If this happens, contact your dealer.)

To be sure that a fuel meets the required properties,

enlist the aid of a reputable fuel oil supplier. The

responsibility for clean fuel lies with the fuel supplier

as well as the fuel user.

FUEL STORAGE

Take the following precautions to ensure that stored

fuel is kept free of dirt, water and other contaminants.

•

Store fuel in black iron tanks, not galvanized

tanks, as the zinc coating will react with the fuel

and form compounds that will contaminate the

injection pump and injectors.

•

Install bulk storage tanks away from direct

sunlight and angle them slightly so sediment in

the tanks will settle away from the outlet pipe.

•

To facilitate moisture and sediment removal,

provide a drain plug at the lowest point at the end

opposite the outlet pipe.

•

If fuel is not filtered from the storage tank, put a

funnel with a fine mesh screen in the fuel tank

filler neck when refuelling.

•

Arrange fuel purchases so summer grade fuels

are not held over and used in winter.

Summary of Contents for T6010 DELTA

Page 1: ...OPERATOR S MANUAL T6010 T6020 T6030 T6050 T6070 Delta and Plus Tractors ...

Page 6: ...BLANK ...

Page 28: ...SECTION 1 GENERAL INFORMATION AND SAFETY 1 22 NOTES ...

Page 280: ...SECTION 3 FIELD OPERATION 3 146 NOTES ...

Page 366: ...SECTION 5 FAULT FINDING 5 12 NOTES ...

Page 368: ...SECTION 6 VEHICLE STORAGE 6 2 NOTES ...

Page 400: ...SECTION 8 SPECIFICATIONS 8 24 NOTES ...

Page 402: ...SECTION 9 1ST 50 HOUR SERVICE SHEETS 9 2 ...

Page 404: ...SECTION 9 1ST 50 HOUR SERVICE SHEETS 9 4 ...

Page 410: ...SECTION 10 INDEX 10 6 ...

Page 412: ...sblank ...