Engine - Engine and crankcase

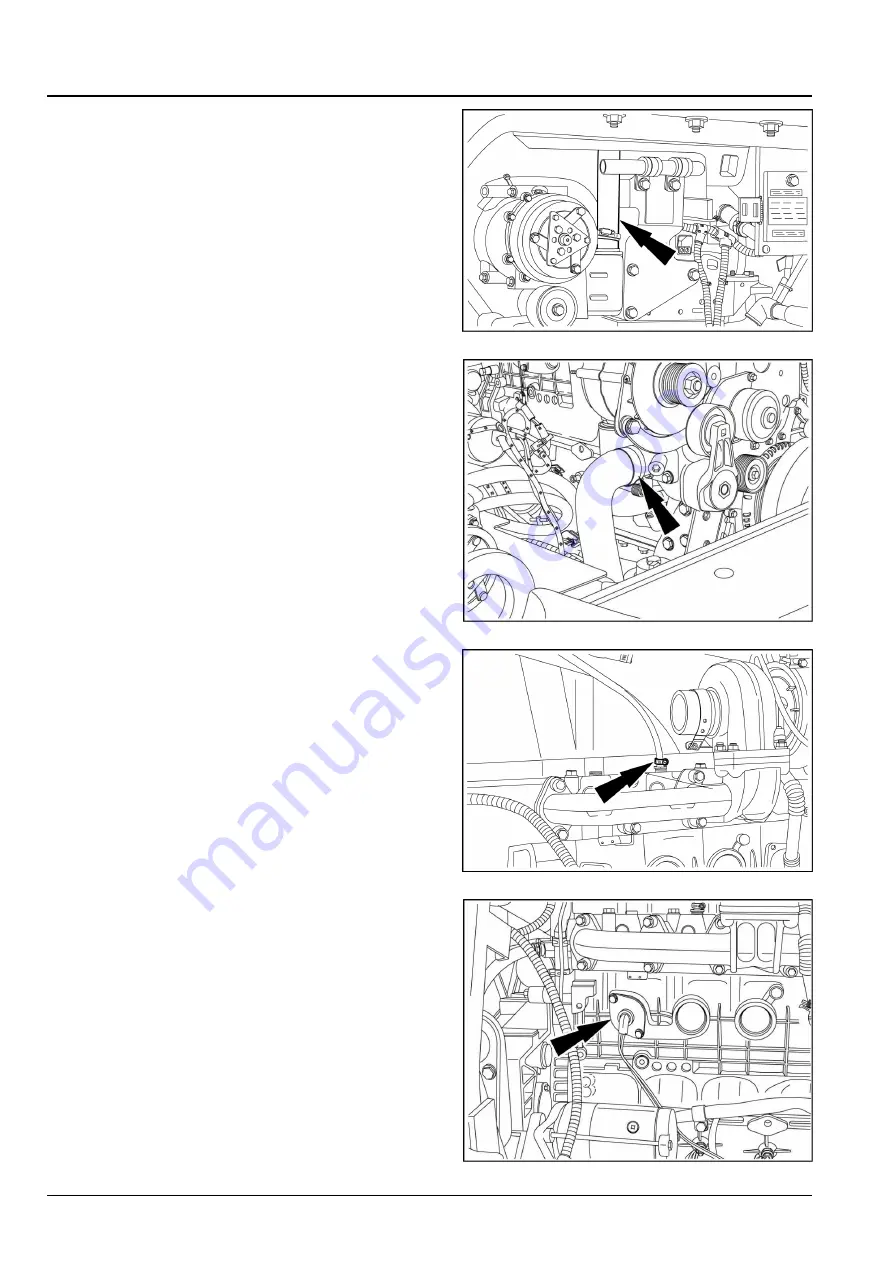

41. Connect the radiator hose to the engine. Tighten the

clamp to

10.1 – 11.3 N·m

(

7.4 – 8.3 lb ft

).

LEIL13WHL0159AB

42

42. Connect the lower coolant hose to the engine and

tighten the clamps.

Tighten the clamp to

10.1 –

11.3 N·m

(

7.4 – 8.3 lb ft

).

RAPH12WEL0629AA

43

43. Connect the engine coolant vent hose to the engine

and secure the clamp. Tighten the clamp to

3.4 N·m

(

2.5 lb ft

).

LEIL13WHL0158AB

44

44. Connect the engine block heater if machine is so

equipped.

RAPH12WEL0626AA

45

51428248_EN 18/12/2017

10.1 [10.001] / 42

Summary of Contents for W130D

Page 7: ...51428248_EN 18 12 2017 Find manuals at https best manuals com ...

Page 8: ...INTRODUCTION 51428248_EN 18 12 2017 1 Find manuals at https best manuals com ...

Page 33: ...INTRODUCTION LEIL17WHL1339FA 3 W130D LEIL17WHL1060FA 4 W170D 51428248_EN 18 12 2017 26 ...

Page 35: ...INTRODUCTION 51428248_EN 18 12 2017 28 ...

Page 81: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com ...