5

1

1

.

.

A

A

p

p

p

p

e

e

a

a

r

r

a

a

n

n

c

c

e

e

2

2

.

.

P

P

a

a

r

r

t

t

n

n

a

a

m

m

e

e

s

s

a

a

n

n

d

d

a

a

c

c

c

c

e

e

s

s

s

s

o

o

r

r

i

i

e

e

s

s

N

N

o

o

.

.

P

P

a

a

r

r

t

t

N

N

a

a

m

m

e

e

D

D

e

e

s

s

c

c

r

r

i

i

p

p

t

t

i

i

o

o

n

n

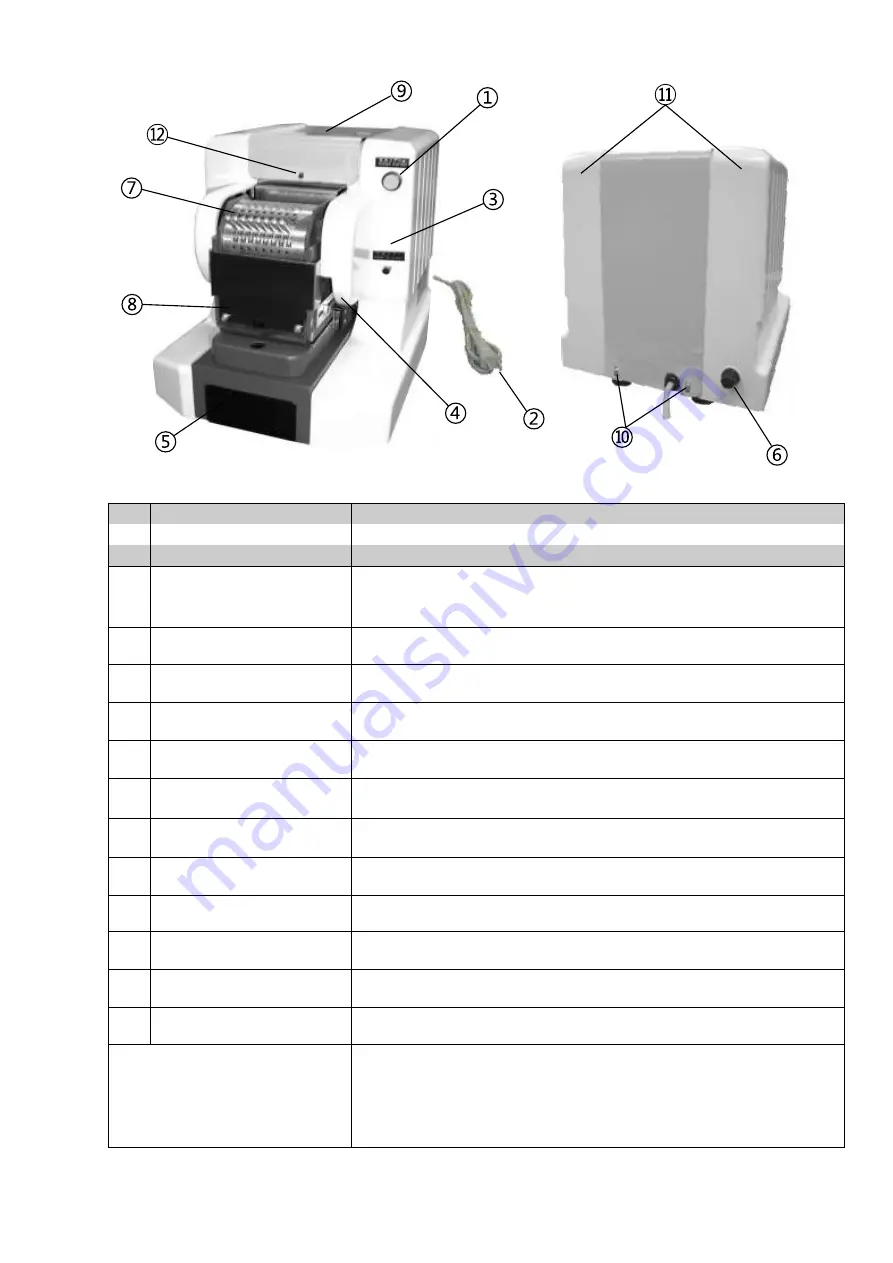

①

Main Switch

Push button switch that turns on the power supply.

(The green lamp lights up.)

②

Electric cord with plug

Plug unit into a suitable wall outlet.

③

Operating switch

Push button for manual operation if the depth switch cannot be used.

④

Micro switch

Switch for detecting when paper is inserted and the machine can punch.

⑤

Waste Drawer

Drawer for paper chip storage. Must check and empty it frequently (it is

advisable to check daily).

⑥

Fuse box

Turns off the power when an excessive electric load is applied to the product.

⑦

Die block

This is the perforation die block.

⑧

Feed opening

Paper insertion area.

⑨

Top cover

A green protective cover is attached. (Please peel off before using).

⑩

Truss head screw

Screws for attaching the top cover.

⑪

Side covers

Left and Right Side Covers

⑫

Pin

This pin fits into the hole in front of the cover when installing the top cover.

Accessory bag list

1 each Operating manual

1 each

spare fuse (5 amp)

1 each 6mm L shape hexagonal wrench

1 each dust cover

Summary of Contents for 10 Series

Page 17: ...17 ...