- 39 -

XT3 TYPE II

www.NewLeader.com

(800) 363-1771

316535-AA-A

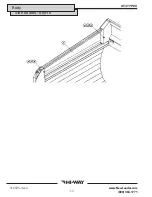

Header

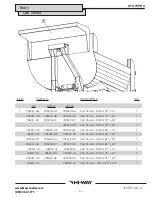

Tailgate & Tailgate Latch

Pump multi-purpose grease into zerks. Oil all pivots and yoke threads monthly with heavy oil.

Bearings

Grease in a bearing acts to prevent excessive wear of parts, protects ball races and balls from corrosion

and aids in preventing excessive heat within the bearing. It is very important the grease maintains its

proper consistency during operation. It must not be

fl

uid and it must not channel.

Make sure that all

fi

ttings are thoroughly cleaned before grease is injected. Points to be lubricated by

means of a grease gun have standard grease

fi

ttings.

Bearings should be lubricated by pumping grease in slowly until a slight bead forms around the seals. This

bead indicates adequate lubrication and also provides additional protection against the entrance of dirt.

Bushings

Do not grease hinge or hoist cylinder self-lubricating bushings. Check bushings monthly to make sure

they are secure and not worn. Make sure hoist cylinder bolts are tightened to recommended torque.

Hoist Cylinder

Cylinder should be lubricated by pumping grease into the zerk slowly until slight bead forms around

the seals. This bead indicates adequate lubrication and also provides additional protection against the

entrance of dirt.

Be sure that all

fi

ttings are thoroughly cleaned before grease is injected. Points to be lubricated by means

of a grease gun have standard grease

fi

ttings.

Fasteners

Tighten all screw fasteners to recommended torques after

fi

rst week of operation and annually thereafter.

If loose fasteners are found at anytime, tighten to recommended torques. Replace any lost or damaged

fasteners or other parts immediately upon

fi

nding such damage or loss.

Clean-Up

Maintain a minimum maintenance operation by washing this equipment thoroughly every two or three

days during the operating season. Hose the unit down under pressure to free all sticky and frozen material.

It is important that the machine be thoroughly cleaned at the end of each operating season. All lubrication

and maintenance instructions listed in this section should be closely followed. For longer body life, repaint

worn spots to prevent the formation of rust.

Lubrication & Maintenance

Summary of Contents for Hi-Way XT3 TYPE II

Page 6: ...Insert Current HI WAY Warranty Warranty...

Page 46: ...46 www NewLeader com 800 363 1771 316535 AA A XT3 TYPE II Cradle Body...

Page 52: ...52 www NewLeader com 800 363 1771 316535 AA A XT3 TYPE II Side Boards Bolt In Body...

Page 58: ...58 www NewLeader com 800 363 1771 316535 AA A XT3 TYPE II Body Lubrication Cont Lubrication...

Page 66: ...66 www NewLeader com 800 363 1771 316535 AA A XT3 TYPE II Domed Screens...

Page 70: ...70 www NewLeader com 800 363 1771 316535 AA A XT3 TYPE II Drive Idler Conveyor...

Page 74: ...74 www NewLeader com 800 363 1771 316535 AA A XT3 TYPE II Chain Shield 4 BOC Conveyor...

Page 92: ...92 www NewLeader com 800 363 1771 316535 AA A XT3 TYPE II Spinner Front Cross Conveyor...

Page 96: ...96 www NewLeader com 800 363 1771 316535 AA A XT3 TYPE II Decals...