P l e a s e G i v e P a r t N o . , D e s c r i p t i o n a n d U n i t S e r i a l N o .

HIGHWAY EQUIPMENT COMPANY

21

97372-B

Page Rev. A

INSTALLATION INSTRUCTIONS CONTINUED

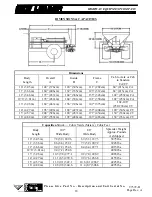

HYDRAULIC PUMP INSTALLATION

A mounting bracket for the hydraulic pump is shipped with the spreader. It may be necessary to

modify this bracket to fit your truck since many variable factors such as PTO make and model, muffler

position, transmission make and model, etc., all affect the mounting position. DO NOT WELD THE

BRACKET TO THE TRUCK FRAME. To do so may void the truck manufacturer’s warranty.

Position the mounting bracket so that the pump drive shaft will be as straight as possible. In no case

should the angle of any universal joint exceed 15º. The pump shaft and PTO shaft should be parallel.

(Figure 1)

HYDRAULIC PUMP DRIVE SHAFT INSTALLATION

The pump drive shaft included may be too long for some installations. It may be cut and redrilled as

necessary. When redrilling the shaft, be sure that universal joints are properly “timed”, as shown in

Figure 1.

Install the slip joint at the end of the pump drive shaft. Failure to install the slip joint will result in

bearing failure in pump, PTO or both.

Figure 1 - Timing of Universal Joints

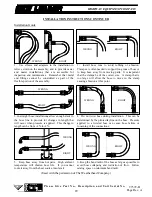

RADAR & CONTROLLER INSTALLATION

See control manual for installation instructions of radar, control box and cable routing.

Parallel Shafts

Not To Exceed

15 Degrees

Parallel Forks

All holes in the truck cab walls, floor and firewall for control wires, hoses

and cables are to be grommeted, plugged and sealed to prevent entrance of

engine fumes, dust, dirt, water and noise.

CAUTION

Summary of Contents for L3020G4

Page 2: ......

Page 6: ...INSERT NEW LEADER NL WARRANTY ...

Page 7: ...TAB SAFETY ...

Page 20: ...TAB OP MAINT ...

Page 111: ...TAB G4 Spread Pattern ...