P l e a s e G i v e P a r t N o . , D e s c r i p t i o n a n d U n i t S e r i a l N o .

HIGHWAY EQUIPMENT COMPANY

55

97372-B

Page Rev. A

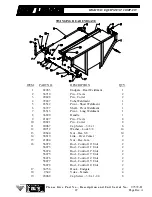

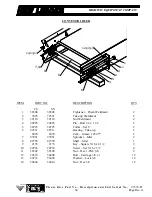

CONVEYOR DRIVE

11,12

6

1

7,8,9

10

13,14

3,4,5

2

15,16

6

2

3,4,5

7,8,9

1

ITEM

PART NO.

DESCRIPTION

QTY

CS

SS

1

86999

86999

Shaft – Drive

1

2

6465

6465

Bearing

2

3

88276

88276

Sprocket

2

4

20743

20743

Screw – Set 5/16 x 3/8

4

5

6131

6131

Key – Square 3/8 x 1 1/2

2

6

82882

82885

Guide – Bearing

4

7

20068

36399

Cap Screw - 3/8 x 1 1/4

8

8

20712

36420

Washer – Lock 3/8

8

9

20644

36414

Nut – Hex 3/8

8

10

82550

82552

Bracket – Torque Arm LH

1

11

20833

20833

Pin – Cotter 1/4 x 1 1/2

1

12

2716

2716

Washer – Flat 3/4

2

13

20128

20128

Cap Screw - 1/2 x 1 1/4

2

14

20680

20680

Nut – Lock 1/2

2

15

37010

37010

Key – Square 1/2 x 1 1/2

2

16

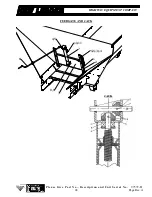

Gear Case Assembly – Refer to

“Control Hydraulics”

Summary of Contents for L3020G4

Page 2: ......

Page 6: ...INSERT NEW LEADER NL WARRANTY ...

Page 7: ...TAB SAFETY ...

Page 20: ...TAB OP MAINT ...

Page 111: ...TAB G4 Spread Pattern ...