99

Test Results

After navigating the course, shut the spreader down and park in a secure location�

Using the funnel, transfer the contents of each collection tray into its corresponding test tube beginning

at one end of the trays and working towards the opposite end�

If spreading a blend of materials, inspect all tubes to determine if the blend is consistent across the entire

swath width� If the blend is not consistent, use a narrower swath width� The swath width should be based

on the material thrown the shortest distance�

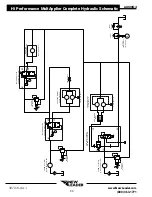

Record each test tube’s volume in the box on the data sheet under the corresponding tray position and

graph the spread pattern profile. See Figure 4.

313964-A

Temperature:

°F

lbs/acre

Spinner Speed:

RPM

Controller Vehicle Speed:

MPH

Controller Swath Width:

10’

15’

20’

25’

30’

35’

40’

45’

50’

55’

-0-

10’

15’

20’

25’

30’

35’

40’

45’

50’

55’

1

2

3

4

5

6

7

1

2

3

4

5

6

7

60’

60’

3.5

3.0

3.0

3.03.0

3.0

3.0

2.5

2.5

2.5 2.5 2.5 1.50.5

2.5 2.5

2.0

1.5

0.5

Figure 4

Looking at the material in the test tubes and the graphed profile on the data sheet, compare the overall

shape of the spread pattern to the three acceptable patterns, shown in Figure 5� If an acceptable pattern

has not been achieved, proceed to “Troubleshooting”� Once an acceptable pattern has been achieved,

proceed to “Determining Driving Centers”�

FLAT TOP

OVAL

PYRAMID

RA

TE/A

CRE

RA

TE/A

CRE

RA

TE/A

CRE

Figure 5 – Acceptable Patterns

Spread Pattern

L4000G4

www.NewLeader.com

(800) 363-1771

307074-AA-I