- 84 -

www.NewLeader.com

(800) 363-1771

306375-AA-E

L5034G4 AGCO

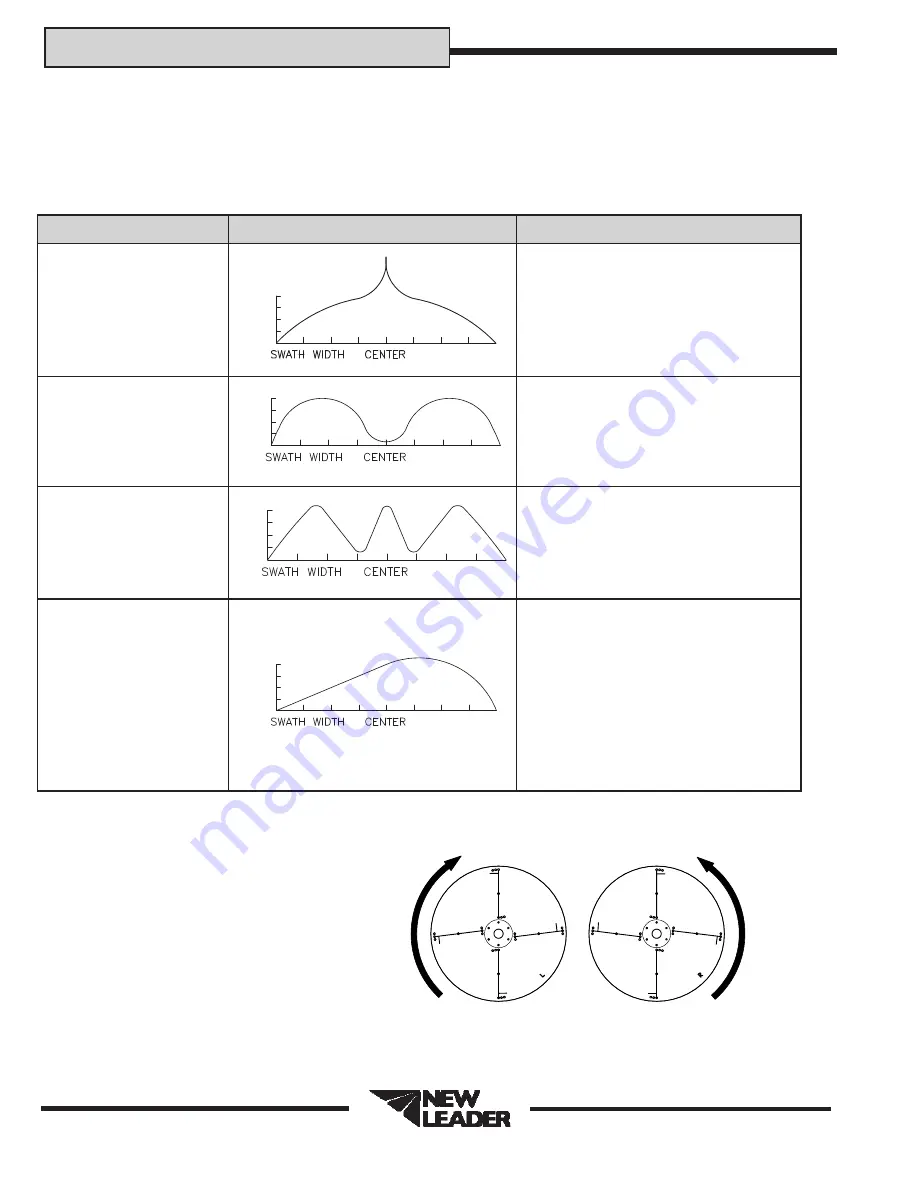

Spread Pattern

NOTE: It is highly recommended that ONLY ONE ADJUSTMENT be made between test samples taken�

If more than one adjustment is made, it will be difficult to determine which adjustment was responsible for

the change in pattern shape�

Problem

Pattern

Recommended Adjustments

Heavy Directly Behind

the Vehicle

RA

TE/ACRE

1� Move the spinner forward

(toward the conveyor)�

Light Directly Behind the

Vehicle

RA

TE/ACRE

1� Move the spinner rearward (away

from conveyor)�

Light Outside Vehicle’s

Tire Tracks

RA

TE/ACRE

1�

Check spinner fins for material

buildup, rust or paint�

2� Increase spinner RPM�

3�

Move spinner fins to 2 - 3 - 2 - 3

positions� See Figure below�

Pattern Off Center

RA

TE/ACRE

1� Check to see feedgate is level

and free of caked material�

2� Make sure hillside divider spinner

assembly and material divider

are mounted squarely and

centered�

3� Testing should be done parallel

to wind�

Spinner fins are adjustable to radial angle

as shown in Figure 7� Refer to Figure 6 for

fin adjustment recommendations.

3

2

1

1

2

3

1

1

2

2

3

3

1 2 3

1

2

3

3

3

2

2

1 1

Figure 7 - Spinner Fin Adjustment

Troubleshooting

Figure 6